in the rapidly evolving realm of automation and robotics, precision stands as a cornerstone of efficiency and performance.As industries strive for greater accuracy, the demand for advanced control systems intensifies. At the heart of this technological pursuit lie low-voltage DC drivers/” title=”Diamond Plus Series Pin Servo Drivers”>servo drivers—unsung heroes that bridge the gap between raw power and precise motion control. These compact yet potent devices enable everything from intricate robotic movements to the seamless operation of conveyor systems, making them vital components in modern engineering solutions. This article delves into the essentials of low-voltage DC servo drivers, exploring their functionality, applications, and the innovations that are shaping their future.Join us on a journey to unlock the precision that these critical devices offer, illuminating the path towards a more automated world.

Table of Contents

- understanding Low-Voltage DC Servo Drivers and Their Role in Modern Automation

- key Features to Consider for Optimal Performance and Efficiency

- Practical Applications that Showcase the Versatility of Servo Drivers

- Troubleshooting Common Challenges for Enhanced Reliability and Longevity

- Q&A

- final Thoughts

Understanding Low-Voltage DC Servo Drivers and Their Role in Modern Automation

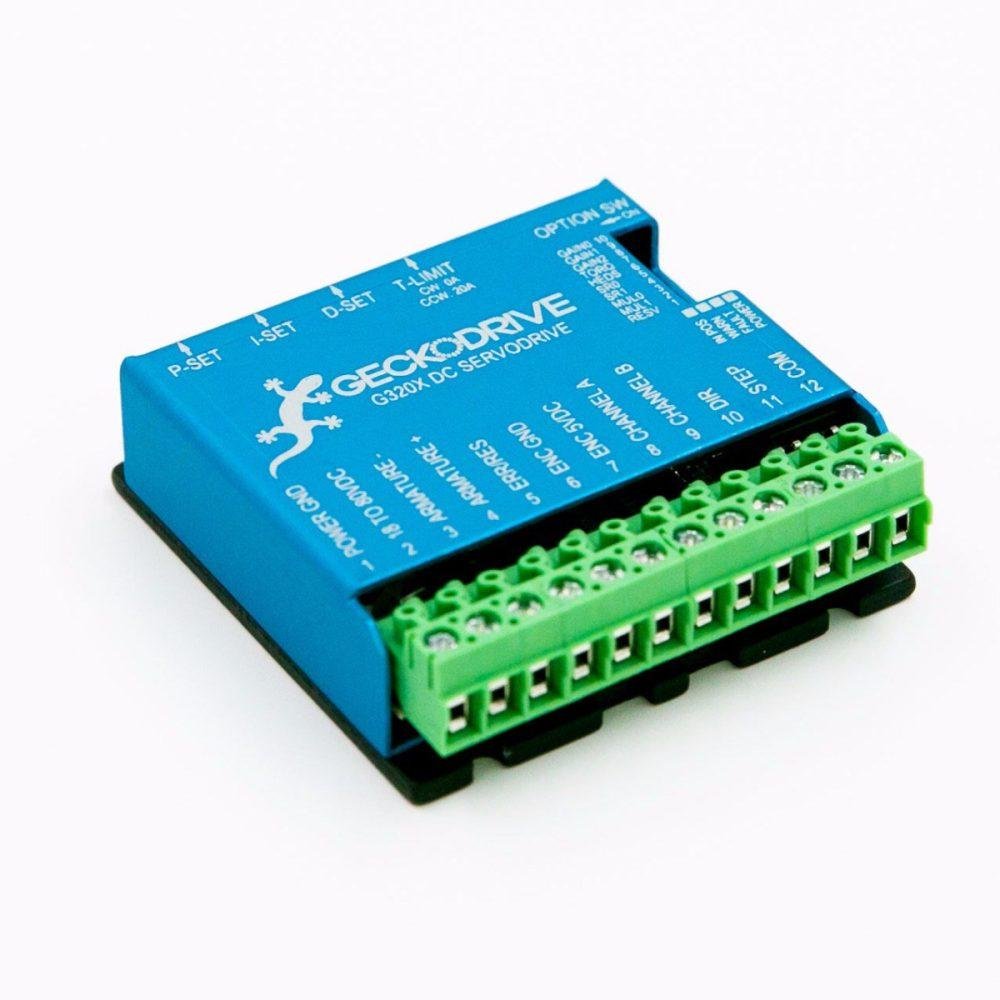

In the realm of automation, low-voltage DC servo drivers play an indispensable role in controlling the motion of various machinery with unparalleled precision. These devices enable the accurate regulation of motor speed, position, and torque, ensuring that operations run smoothly and efficiently. By converting input signals into precise voltage and current outputs, they allow for real-time adjustments to be made, catering to the dynamic requirements of modern automation systems.

One of the primary advantages of utilizing low-voltage DC servo drivers is their ability to enhance performance in applications that demand high accuracy. These drivers typically feature advanced feedback systems that monitor the position and speed of the motor. This closed-loop control mechanism helps in minimizing errors, which is critical in settings such as robotics, CNC machinery, or any application where precision is paramount. key features include:

- High-resolution feedback: Ensures the motor’s position is consistently monitored and adjusted.

- Compact design: Ideal for applications with limited space without compromising power output.

- Energy efficiency: Operates effectively at lower power levels, reducing operational costs.

Furthermore, the integration of low-voltage DC servo drivers with contemporary automation technologies propels industries toward greater innovation. These drivers are compatible with various communication protocols, facilitating seamless connectivity in networked systems. This compatibility allows for the implementation of technologies such as iot, enabling remote monitoring and control of machinery. The table below illustrates some critical specifications of contemporary low-voltage DC servo drivers:

| specification | Typical Value |

|---|---|

| Input voltage Range | 12V - 48V |

| Control Method | PWM/Analog |

| feedback type | Incremental/Absolute Encoders |

| Max Output Current | 10A – 25A |

Key Features to Consider for Optimal Performance and Efficiency

When selecting low-voltage DC servo drivers, several key features can significantly influence their performance and efficiency. One critical aspect is closed-loop control capabilities, which allow the servo system to constantly monitor and adjust its output based on feedback. This dynamic interaction ensures precision in positioning and velocity, minimizing errors during operation. Additionally, it’s important to consider high-frequency response, as it enables the driver to react swiftly to changes in command signals, resulting in smoother, faster, and more accurate motion control.

Another essential feature is compactness and thermal management. space constraints are common in many applications,making it crucial to select drivers that are both efficient in performance and compact in design. Look for systems that incorporate advanced heat dissipation technologies to maintain optimal operating temperatures, preventing overheating issues that can lead to decreased lifespan and reliability. Also, ensure that the selected driver supports modular expansion options, which allow for future scalability as system demands evolve.

Lastly, don’t overlook the significance of communication protocols within your choice of servo driver. compatibility with various industrial protocols like CANopen, EtherCAT, or RS-485 can enhance integration with existing automation systems. This flexibility facilitates seamless data exchange and monitoring, ultimately improving overall system robustness.Additionally, check for fault detection mechanisms, which can provide real-time alerts to prevent potential issues before they escalate, contributing greatly to system reliability and maintenance efficiency.

Practical Applications That Showcase the Versatility of Servo Drivers

Servo drivers are integral components across various industries, effectively transforming the control of motors into precise mechanical actions. One prime example is in robotic arms, where low-voltage DC servo drivers allow for extraordinary accuracy in tasks ranging from assembly to surgical procedures. By enabling smooth and precise movements,these drivers facilitate intricate operations that require consistency and reliability,ensuring that even the most delicate tasks are carried out flawlessly.

In the realm of automated industrial processes, servo drivers play a critical role. They are utilized in conveyor systems, enhancing the speed and precision of material handling and assemblies. As an example, when applied in packaging lines, DC servo drivers can manage the exact positioning of products, ensuring they are packed efficiently without human intervention. This boosts production efficiency while reducing the risk of errors, thus maintaining product quality. Additionally, these systems can adapt to fluctuations in demand, changing speeds and positions to accommodate varying production rates.

The innovation continues in the aerospace and automotive sectors, where low-voltage DC servo drivers are crucial in systems such as flight control surfaces and precision steering mechanisms.They enable real-time adjustments to control inputs, ensuring the highest safety standards. With their capability for high-torque output and responsiveness, these servo drivers facilitate complex maneuvers that are essential for maintaining stability and performance in high-stress environments. The versatility of servo drivers in these applications not only enhances operational effectiveness but also contributes to notable advancements in engineering and technology.

Troubleshooting Common Challenges for Enhanced Reliability and Longevity

When it comes to optimizing low-voltage DC servo drivers, users often encounter several common challenges that can hinder performance. Electrical noise is a frequent issue that can disrupt signal integrity, leading to erratic operations.To mitigate this, employing proper grounding techniques and minimizing cable lengths can significantly improve reliability. Additionally, the use of shielded cables can help in isolating electrical interference from external sources.

Another recurring challenge is thermal management. Inadequate cooling can lead to overheating, thereby reducing the overall lifespan of the servo drivers. Users should consider implementing effective cooling solutions, such as heatsinks or active ventilation systems, especially in environments with limited airflow. It is indeed also imperative to monitor temperature levels regularly to ensure they remain within the manufacturer’s specified operating range.

software integration issues can also affect the performance of servo drivers. Incompatible firmware or outdated software can lead to communication failures between the driver and the control system. To address this, always ensure that the latest firmware updates are applied, and conduct regular system audits to check for compatibility issues. The following table summarizes essential maintenance tips for enhanced reliability:

| Maintenance Tip | Description |

|---|---|

| Regular Inspections | Conduct routine checks on connections and components. |

| Firmware Updates | Keep software up-to-date to prevent compatibility issues. |

| Thermal Monitoring | Implement temperature sensors to track heat levels. |

| Noise Reduction | Utilize shielding and proper cabling to minimize interference. |

Q&A

Q&A: Unlocking Precision – The Essentials of Low-Voltage DC Servo Drivers

Q: What exactly are low-voltage DC servo drivers, and how do they work?

A: Low-voltage DC servo drivers are electronic devices that control the motion of DC servo motors while providing precise feedback for position, speed, and torque.They function by taking signals from a control system and adjusting the power sent to the motor, ensuring accurate movement and control. This is achieved through algorithms that continuously adjust the output based on feedback from the motor’s position sensor.

Q: What are the key benefits of using low-voltage DC servo drivers?

A: The primary benefits include enhanced precision and responsiveness, reduced power consumption, and greater system integration capabilities. These drivers allow for smooth operation at lower voltages, which often translates to prolonged equipment life and less heat generation. Additionally, they typically feature compact designs that make them ideal for applications with spatial constraints.

Q: In which applications are low-voltage DC servo drivers commonly used?

A: These drivers are widely utilized across various industries, including robotics, automated machinery, CNC equipment, and medical devices. They excel in applications requiring fine control, such as in positioning systems, 3D printing, and even in consumer electronics, where accurate motion control is essential for optimal performance.

Q: What are some considerations when selecting a low-voltage DC servo driver?

A: When choosing a driver, consider factors such as the torque and speed requirements of your application, the voltage and current ratings of the motor, and the type of feedback system in place (like encoders or resolvers). Additionally, look for features such as programmability, thermal protection, and ease of integration with existing systems.

Q: How do low-voltage DC servo drivers contribute to energy efficiency?

A: These drivers optimize power usage by only providing the necessary amount of energy to the motor depending on the required load. This adaptive approach minimizes wasted energy, contributing to overall system efficiency. Moreover,operating at lower voltages frequently enough reduces energy costs,making them a more lasting choice for long-term operations.

Q: Can you explain the role of feedback in low-voltage DC servo systems?

A: Feedback is crucial in servo systems as it allows the driver to measure how well the motor is performing against the desired output. By using sensors to provide real-time data on position, speed, and torque, the driver can make rapid adjustments to maintain accuracy and responsiveness, effectively creating a closed-loop control system.

Q: What trends are shaping the future of low-voltage DC servo drivers?

A: The shift towards more integrated and intelligent systems is a significant trend. As IoT technologies and smart sensors grow in prevalence, low-voltage DC servo drivers are expected to incorporate more advanced communication protocols and data analytics capabilities. This will enhance their adaptability and functionality in complex automation environments, driving innovation across many sectors.

Q: How dose one maintain low-voltage DC servo drivers for optimal performance?

A: Regular maintenance should include checking for loose connections, ensuring proper cooling, and calibrating the drivers alongside their respective motors. Keeping the firmware updated can also unlock new features and improve efficiency. Lastly, reviewing performance logs can help identify any irregularities early on, preventing potential breakdowns.

Q: Where can I learn more about low-voltage DC servo drivers?

A: A variety of resources are available, including manufacturer guides, technical whitepapers, and online courses that delve deeper into servo technology. Engaging with industry forums and attending workshops can also provide valuable insights and updates on the latest advancements in low-voltage DC servo drivers.

Final Thoughts

As we draw the curtain on our exploration of low-voltage DC servo drivers, it’s clear that these unassuming components are anything but simple. They represent the marriage of precision and efficiency, breathing life into the realm of automation with their remarkable capabilities. By mastering the essentials outlined in this article, engineers and hobbyists alike can harness the true potential of these drivers, steering their projects toward unparalleled accuracy and responsiveness.

Whether you’re a seasoned professional or just beginning your journey in motion control, understanding the nuances of low-voltage DC servo drivers is a key that unlocks a world of possibilities.So, as you embark on your next endeavor, remember that the power of precision is not merely a technical aspiration; it’s a pathway to innovation. Embrace the fundamentals, tinker fearlessly, and let your creativity guide you, for in the realm of servo technology, the only limits are those of your inventiveness.