in an era defined by rapid technological advancement,the quest for precision has permeated every sector,from aerospace to robotics. At the heart of this pursuit lies the often-overlooked micro servo <a href="https://ydservo.com/product/diamond-plus-series-pin-servo-drivers/” title=”Diamond Plus Series Pin Servo Drivers”>driver—a small but mighty component that has evolved dramatically over the years. As miniature devices gain prominence in an increasingly automated world, understanding the journey of micro servo drivers unveils a fascinating narrative of innovation, engineering ingenuity, and a relentless quest for accuracy. This article embarks on an exploration of how these unassuming drivers have transformed from rudimentary controls to complex systems capable of delivering unparalleled performance, revolutionizing applications that demand the utmost precision. Join us as we delve into the intricacies of micro servo drivers and the pivotal role they play in shaping the future of technology.

Table of Contents

- Exploring the Fundamental Mechanics of Micro Servo Drivers

- Advancements in Control Algorithms for Enhanced Performance

- Selecting the Right Micro Servo Driver for Your Applications

- Future Trends: Innovations Shaping the Next Generation of Servo Technology

- Q&A

- Future Outlook

Exploring the Fundamental Mechanics of Micro Servo Drivers

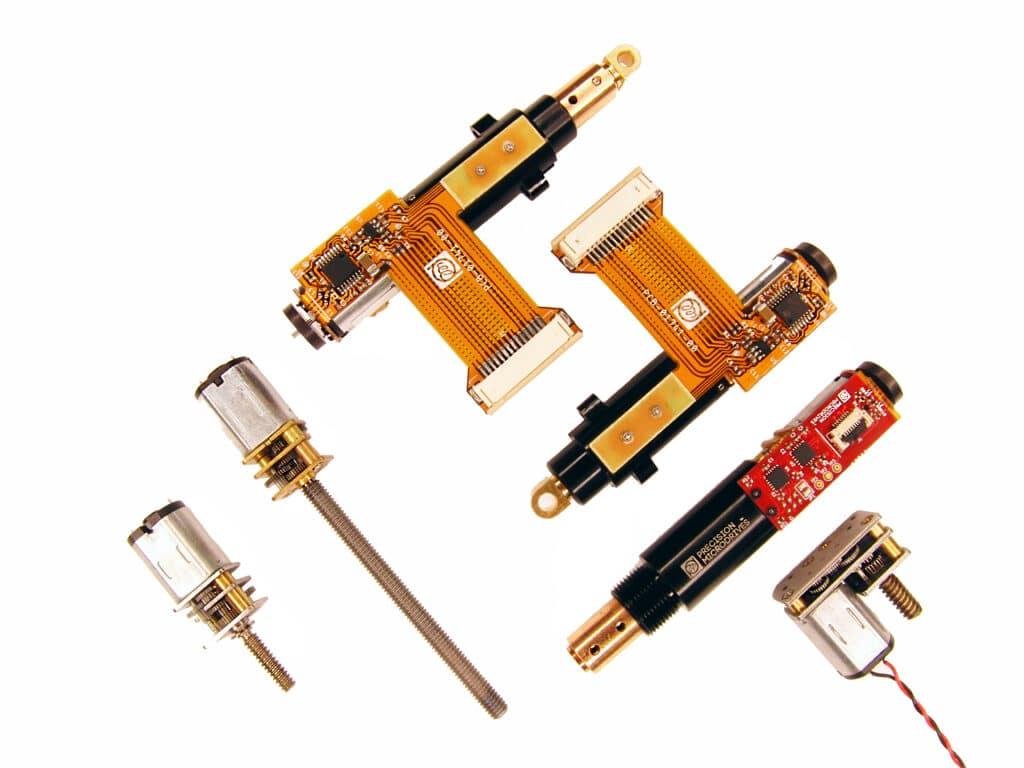

In the realm of robotics and automation,micro servo drivers serve as the heartbeat,enabling remarkable precision and control. These compact units convert electrical signals into mechanical movement, allowing for intricate maneuvers in devices like drones, remote-controlled cars, and robotic arms. The underlying mechanics are fascinatingly simple yet profound, comprising a motor, a gear train, and a feedback mechanism, all of which work in harmony to bring commands to life. By manipulating the pulse-width modulation (PWM) signals sent to the micro servo, controllers summon exceptionally fine movements that are essential for applications where accuracy is paramount.

At the core of a micro servo driver lies its gear train, which reduces the motor speed while amplifying torque. This relationship between speed and torque plays a crucial role in the application of servos, as it allows them to move heavier loads with precision. When evaluating servo drivers, users must consider key specifications including stall torque, speed, and range of motion, which collectively determine the capabilities of the system. The selection of the right micro servo driver can considerably enhance the performance of a project, leading to innovative designs and successful implementations.

Additionally,advancements in technology have birthed a new generation of micro servo drivers featuring sophisticated control algorithms and enhanced user interfaces. These developments allow for improved feedback systems, enabling servos to return to a desired position with greater reliability. With features such as programmable settings, onboard sensors, and even wireless connectivity, today’s micro servo drivers are not only more efficient but also remarkably versatile. understanding these mechanics not only aids in the selection of the right components but also inspires hobbyists and professionals alike to push the boundaries of what is possible in automation and robotics.

Advancements in Control Algorithms for Enhanced Performance

The evolution of control algorithms has played a pivotal role in the performance of micro servo drivers, enabling unparalleled precision and responsiveness. Today’s advancements leverage sophisticated algorithms that enhance system stability and accuracy while minimizing response time. Among these, model predictive control (MPC) and adaptive control have emerged as frontrunners, allowing for real-time adjustments based on varying load conditions and operational environments.

Moreover, the integration of machine learning techniques into control algorithms represents a groundbreaking shift.By analyzing historical performance data,these algorithms can predict potential issues and optimize the control strategies accordingly. This shift not only improves overall efficiency but also allows for the fine-tuning of operational parameters, ensuring that micro servo drivers can maintain a steady performance even under fluctuating conditions. Key features of these modern algorithms include:

- Reduced Overshoot: Ensuring better responsiveness without compromising stability.

- Improved Robustness: Enhancing the ability to maintain performance in the face of disturbances.

- Energy Efficiency: Reducing power consumption without sacrificing output.

To illustrate the impact of these advancements, consider the following comparison of customary versus modern control algorithms in micro servo applications:

| Aspect | traditional Control | Modern Control Algorithms |

|---|---|---|

| Response time | Higher latency | Significantly reduced |

| Adaptability | Limited | Highly adaptive |

| Maintenance Overhead | Higher maintenance costs | Lower costs, predictive insights |

With these developments, manufacturers can harness greater performance from micro servo drivers, paving the way for new applications across diverse sectors including robotics, aerospace, and automation. The journey toward achieving pinpoint accuracy and reliability continues as researchers and engineers collaborate to push the boundaries of what’s possible with control algorithms.

Selecting the Right Micro Servo Driver for Your Applications

Choosing the appropriate micro servo driver for your project can significantly enhance the performance and precision of your application. Consider the following key factors to narrow down your options:

- compatibility: Ensure that the servo driver is compatible with the specific type and model of your micro servo, whether it’s a standard or a high-torque variant.

- Control Interface: Look for a driver that supports the control protocol required for your project, such as PWM, I2C, or UART, to facilitate seamless integration.

- Power Requirements: Check the power specifications. A driver that provides adequate voltage and current ratings will help maintain optimal servo performance without overheating or damaging components.

Additionally, think about the environmental conditions your application will face. Some projects may require drivers that can handle extreme temperatures or humidity levels. Look for features such as:

- Durability: Drivers with rugged enclosures or those specifically designed for outdoor use can offer enhanced reliability.

- Protection Features: Over-current, over-voltage, and thermal shutdown protections are crucial for preventing damage in unforeseen circumstances.

- Size and Weight: In applications where space is limited, compact designs are a significant advantage.

Lastly,keep in mind the cost-benefit ratio. High-end micro servo drivers may come with superior features,but they may not always align with the budget constraints of your project. Structure your evaluation based on:

| Feature | High-end Driver | Budget Driver |

|---|---|---|

| Precision Control | ±0.1° | ±1° |

| Max Load Capacity | 5 kg | 2 kg |

| Price | $50 | $15 |

By carefully evaluating these aspects,you can select a micro servo driver that not only meets your technical specifications but also aligns with your project’s goals and budget. A well-chosen driver can be the linchpin of a precisely executed operation.

Future Trends: Innovations Shaping the Next Generation of Servo Technology

The future of servo technology is poised to transform industries thru innovative developments and enhancements in performance. One of the moast anticipated trends is the integration of machine learning algorithms into servo systems.By utilizing real-time data processing and feedback loops,these systems can self-optimise,adapting to varying loads and conditions with remarkable precision.This evolution not only enhances efficiency but also reduces wear and tear on mechanical components, prolonging the operational lifespan of devices.

Additionally, we are witnessing a significant shift towards miniaturization in servo technology.the demand for smaller, more compact devices that do not compromise on power or functionality is driving innovations in micro servo drivers.These advancements are enabling applications in areas previously thoght impossible, such as wearable technology, robotics, and medical devices. As a result, micro servo drivers are becoming integral to the design of numerous cutting-edge gadgets, allowing for greater flexibility in engineering and design.

| Innovation | Impact |

|---|---|

| Machine Learning | Self-optimising systems |

| Miniaturization | Compact designs for varied applications |

| Smart Connectivity | Integration with IoT devices |

As we look ahead, emerging technologies such as smart connectivity will enable seamless integration with IoT systems, facilitating better interaction between devices and leading to improved automation and control scenarios. Innovations like these promise to usher in an era of enhanced interactivity and responsiveness in servo applications, paving the way for sophisticated automated environments. This shift not only benefits manufacturers through streamlined operations but also enhances end-user experiences across various sectors.

Q&A

Q&A: Unleashing precision – The Evolution of Micro Servo Drivers

Q1: What exactly are micro servo drivers, and why are they significant in technology today?

A1: Micro servo drivers are compact devices designed to control small servos, allowing for precise movement and position control in various applications. Their importance lies in their versatility; they power robotics, RC vehicles, drones, and even automation in home devices. As technology continues to shrink in size while demanding greater precision, micro servo drivers emerge as a vital component in the quest for functionality and efficiency.

Q2: How have micro servo drivers evolved over the years?

A2: The evolution of micro servo drivers can be traced from simple, analog controllers to sophisticated digital units. early designs relied on basic pulse-width modulation (PWM) signals for control, limiting accuracy and response times. Today’s drivers utilize advanced algorithms, feedback systems, and microprocessor technology, allowing real-time adjustments and enhanced responsiveness. This shift has significantly improved their performance, resulting in smoother and more precise movements.

Q3: Can you elaborate on the innovations that have impacted micro servo drivers recently?

A3: Certainly! Recent innovations include the integration of digital signal processing (DSP), which permits intricate control schemes and enhances torque and positional accuracy.Additionally, developments in communication protocols, like I2C and CAN, enable micro servo drivers to interface seamlessly with various devices, improving coordination in robotic systems. Another noteworthy advancement is the miniaturization of components, allowing for even more compact and efficient servo systems to be deployed in tight spaces.

Q4: What industries benefit the most from advancements in micro servo drivers?

A4: A multitude of industries benefit from these advancements.Robotics is at the forefront, where precise movement is crucial for tasks ranging from assembly to exploration. The automotive sector harnesses micro servo drivers in applications such as self-parking and advanced driver-assistance systems. In consumer electronics, they are used in everything from camera gimbals to automated pet feeders, showcasing their versatility across various platforms.

Q5: How do micro servo drivers contribute to sustainability in technology?

A5: micro servo drivers contribute to sustainability by promoting energy efficiency and reducing material waste. With their ability to control motion accurately, these drivers can minimize power consumption in devices, leading to longer-lasting battery life in portable applications. Moreover, as technology advances and components become smaller, manufacturers can create products using fewer materials, aligning with eco-friendly design principles.

Q6: What challenges remain in the progress of micro servo drivers?

A6: Despite their advancements, challenges persist. Achieving higher precision at lower costs remains a balancing act for manufacturers. Additionally, as applications become more complex, ensuring system reliability and reducing electromagnetic interference are ongoing concerns.fostering an environment where innovative ideas can flourish and keeping pace with rapid technological change is essential for continued progress in micro servo driver development.Q7: what does the future hold for micro servo drivers?

A7: The future of micro servo drivers looks promising, with trends pointing toward greater integration with artificial intelligence and machine learning. These technologies could empower drivers to adapt better to their environments, leading to smarter applications in robotics and automation. As research and development efforts continue, we can expect micro servo drivers to become more efficient, more robust, and even more integral to our daily lives.

Q8: How can enthusiasts and professionals get involved in the world of micro servo drivers?

A8: Enthusiasts and professionals alike can dive into the world of micro servo drivers by exploring DIY projects, joining online forums, and participating in maker communities. Many open-source platforms and educational resources are available for those looking to learn about the programming and operation of micro servo drivers. Workshops, online courses, and competitions are also excellent avenues to refine skills and connect with others passionate about technology.

Future Outlook

As we close the chapter on the evolution of micro servo drivers, we reflect on a journey marked by innovation, precision, and adaptability. From their humble beginnings in simple robotic applications to their pivotal role in advanced automation and intricate control systems, these compact marvels have transformed the landscape of engineering and technology. The advancements in micro servo driver design not only highlight the relentless pursuit of efficiency but also open doors to future possibilities in automation and robotics that we are only beginning to explore.

With each leap forward, we uncover new potential and applications that challenge our creativity and technical expertise. As we stand at the crossroads of technological advancement and innovation, one thing is certain: the journey of micro servo drivers is far from over. The future holds exciting prospects, inviting engineers and creators alike to harness their precision and versatility. In this relentless quest for perfection, we can only imagine the boundless horizons awaiting us in the world of automation. Let us embrace this evolution and prepare for what lies ahead.