In the ever-evolving realm of robotics, where innovation meets ingenuity, the spotlight is frequently cast on the intricate dance of precision and compactness. At the heart of this intricate choreography lies the micro servo driver, a technology that embodies both finesse and functionality. As robotics applications continue to shrink in size while demanding ever-greater levels of control, these drivers serve as the unsung heroes, enabling miniature machines to perform complex tasks with remarkable accuracy. This article delves into the world of micro servo drivers, exploring how they facilitate precision control in compact robotics, bridging the gap between technological advancement and operational effectiveness. Join us as we uncover the mechanisms, applications, and future potentials of this vital component in the robotic landscape.

Table of Contents

- Understanding Micro Servo Drivers and Their Role in Robotics

- Key features to Consider for Enhanced Precision and Performance

- Optimal Integration techniques for Compact Robotic Systems

- Choosing the Right Micro Servo Driver for Your Project Needs

- Q&A

- The Way Forward

Understanding Micro Servo Drivers and Their Role in Robotics

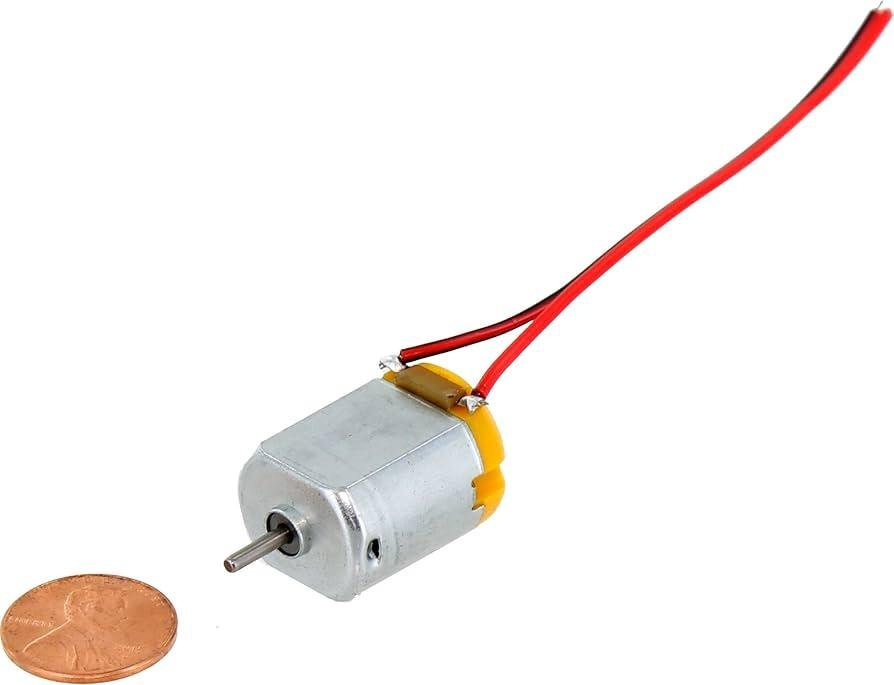

Micro servo drivers are essential components in compact robotics, offering precise control to small actuation systems. These drivers function by interpreting control signals from a microcontroller and converting them into the specific movements of the micro servos. their compact size makes them a popular choice for projects requiring limited space without sacrificing performance. Unlike larger servo systems, micro servo drivers enable smooth and accurate servo motion, crucial for applications such as robotic arms, drones, and even hobbyist projects like remote-controlled vehicles.

One of the meaningful advantages of using micro servo drivers is their ability to operate in a variety of configurations. typically, they can handle different input signals, making them versatile for various applications. Here are some key features of micro servo drivers:

- Compact Size: Perfect for small-scale robotics.

- Precision Control: Allows for fine-tuning of movements.

- Wide Compatibility: works with various control systems.

- Efficiency: Consumes less power compared to larger drivers.

To illustrate their impact on robotics design, consider the following examples of applications where micro servo drivers shine:

| Application | Description |

|---|---|

| Robotic Grippers | Micro servos provide the necesary precision for delicate tasks. |

| Self-Balancing Robots | Enables rapid adjustments to maintain balance. |

| Drones | Powers the tilt mechanism for better aerial maneuverability. |

Key Features to Consider for Enhanced Precision and Performance

When selecting micro servo drivers for compact robotics, several features can significantly influence both precision and performance. Motor compatibility is crucial; ensuring that the driver supports a variety of motor types—including brushed and brushless—is essential for versatility in design. Additionally, the control method employed by the driver can affect responsiveness, with options such as PWM (Pulse Width Modulation) and I2C offering different benefits in terms of integration and fine control.

The feedback system of a servo driver plays a vital role in achieving accurate positioning. Feedback mechanisms,such as encoders or potentiometers,provide real-time data on the rotor’s position,allowing for adjustments that enhance movement accuracy. Furthermore, motion profiles should be considered, as they define how the servo accelerates, decelerates, and maintains speed. customizable profiles can cater to specific applications, promoting smoother operations and reducing mechanical stress.

In addition to technical specifications, size and weight of the driver are significant factors in compact robotics. A lightweight driver integrates seamlessly into constrained spaces without compromising the overall design integrity. Moreover, power efficiency cannot be overlooked; a driver that optimizes energy consumption will not only extend operational runtimes but also minimize heat production, contributing to long-term reliability. effective selection among these features will result in enhanced system precision and performance in robotic applications.

Optimal integration Techniques for Compact Robotic Systems

For compact robotic systems, achieving precision movements requires more than just high-quality components; it necessitates an efficient integration process that maximizes the capabilities of micro servo drivers. By utilizing sensory feedback mechanisms,engineers can ensure that each movement is both accurate and responsive. Such mechanisms include:

- Temperature sensors: Prevent overheating and maintain optimal performance.

- Position encoders: Provide real-time data on servo positioning.

- Gyroscopic sensors: Enhance stability during dynamic motions.

Wiring and circuit design play a pivotal role in the overall performance of micro servo drivers within compact systems. Utilizing PCB layouts designed specifically for micro servos can minimize signal loss and ensure stricter control over power distribution. By implementing dedicated power management approaches, such as incorporating capacitors for charge stabilization, developers enable smoother operation under varying loads. Below is a simplified comparison of conventional vs.optimized PCB layouts:

| Features | Traditional PCB Layout | Optimized PCB Layout |

|---|---|---|

| Signal Integrity | Moderate | High |

| Power efficiency | Low | Enhanced |

| Complexity in Assembly | Higher | Streamlined |

software integration cannot be overlooked when discussing optimal operational techniques for compact robotics. The implementation of efficient algorithms for control systems, such as PID (Proportional, Integral, Derivative) tuning, is essential for achieving fine-tuned responses to inputs. additionally,the use of modular programming allows for easier updates and adaptations to different robotic applications. By focusing on these aspects, developers can harness the full potential of micro servo drivers, ensuring that compact robotic systems function at peak efficiency and reliability.

Choosing the Right Micro Servo Driver for Your Project Needs

When embarking on a robotics project, selecting the right micro servo driver is essential for optimizing performance and ensuring that your design objectives are met.Several factors differentiate micro servo drivers, and understanding these can lead to better choices. Considerations include voltage range, current output, and control methods. Each driver comes with its unique specifications that align with specific applications, be it model-making, automation, or educational robotics.

Compatibility with your microcontroller or development board can significantly influence your decision. Many micro servo drivers are designed with specific protocols in mind, such as PWM, I²C, or UART. When assessing potential drivers, examine their communication interfaces to confirm that they match your control system. In addition, pay close attention to the maximum number of servos that can be controlled simultaneously, as this will impact the scalability of your project.

Lastly, consider the physical dimensions and mounting options of the micro servo driver. In compact robotics, space is often at a premium.Therefore, selecting a driver that fits well within your project’s constraints without sacrificing functionality is crucial. Review options that offer integrated heat dissipation features, reset capabilities, and LED indicators for simplified debug and monitoring.A well-chosen micro servo driver not only enhances your project’s capabilities but also allows for a smoother integration process, paving the way for more innovative designs.

Q&A

Q&A: Micro Servo Drivers – Precision Control for Compact Robotics

Q1: What is a micro servo driver, and how does it work?

A: A micro servo driver is a compact electronic circuit designed to control micro servos, which are small, powerful motors that precision control over rotation and position. These drivers send electronic signals to the servo motor based on the input they receive, often from a microcontroller. By adjusting the pulse width of the signals, the driver dictates the servo’s angle of movement, enabling precise control in various robotic applications.

Q2: Why are micro servo drivers important in compact robotics?

A: In compact robotics, space is often at a premium. Micro servo drivers enable engineers and hobbyists to achieve high levels of control without requiring bulky hardware.Their small footprint makes them ideal for miniature robots,drones,and robotic arms,allowing for intricate movements while conserving valuable space. This efficiency is crucial in designs where every millimeter counts.

Q3: What are some typical applications of micro servo drivers in robotics?

A: micro servo drivers are incredibly versatile and find applications in a variety of robotic systems, including robotic arms for pick-and-place tasks, miniature drones for agile flight, and educational robots used for teaching principles of automation and robotics. They are also used in animatronics, providing realistic movements in models and figures, as well as in remote-controlled toys that require precise maneuverability.

Q4: How does precision control benefit robotic performance?

A: Precision control is essential for tasks that demand accurate positioning, such as assembly line automation or surgical robots. With micro servo drivers, the fine-tuning of motor movements allows for smoother operation and minimizes the risk of errors. This leads to enhanced reliability, improved performance, and the ability to execute complex tasks with confidence, all of which are critical for advanced robotic systems.

Q5: Can micro servo drivers be used with other types of motors?

A: While micro servo drivers are specifically designed for controlling servo motors, there are variants and related technologies that can be adapted for different motor types. As an example, brushless DC motors may require specific drivers, whereas stepper motors utilize control techniques unique to their operational requirements. Nonetheless, the precise control advantages that micro servo drivers offer make them particularly suited for servos in compact robotic solutions.

Q6: What should a builder consider when selecting a micro servo driver for their project?

A: When selecting a micro servo driver,builders should consider factors like the voltage and current ratings of the servo,compatibility with their control system (like Arduino or Raspberry Pi),and the precision requirements of their application. Additionally,evaluating the ease of integration,programming flexibility,and available support or documentation can significantly enhance the project’s development experience.Q7: What are the future trends for micro servo drivers in robotics?

A: The future of micro servo drivers is on an exciting trajectory, with trends leaning towards miniaturization, increased efficiency, and smarter control algorithms. The integration of advanced sensors and artificial intelligence will likely enhance their capabilities, enabling more complex movements and adaptability in dynamic environments. As robotics continues to evolve, so too will the innovations in micro servo technology, paving the way for more advanced applications and possibilities in the realm of compact robotics.

This Q&A format covers various aspects of micro servo drivers, providing readers with a concise yet informative overview of their importance in compact robotics.

The Way forward

as we delve deeper into the world of compact robotics, the significance of micro servo drivers becomes increasingly pronounced. These small yet mighty components embody the essence of precision control, allowing engineers and hobbyists alike to breathe life into innovative designs with unmatched accuracy. Whether you are crafting intricate mechanisms for a robotic arm or fine-tuning a delicate drone, understanding the capabilities and applications of micro servo drivers is integral to your success.

In this rapidly evolving field, the integration of technology, creativity, and engineering principles is paramount. By harnessing the power of these micro servo drivers, you can elevate your robotic projects from mere concepts to functional masterpieces. The future of robotics is not just about size and power; it’s about the finesse with which we manipulate motion and create responsive systems.

As you venture forth with new insights and ideas, remember that every great invention is a step towards a more connected and automated world.With micro servo drivers in your toolkit, the possibilities are indeed limitless. Welcome to the next frontier of precision and innovation.