In an era where technology continues to intertwine seamlessly with our daily lives, the quest for precision has never been more critical. From robotics and automation to consumer electronics, the demand for heightened accuracy in movement and control is propelling innovation to new heights. Enter micro drivers/” title=”Diamond Plus Series Pin Servo Drivers”>servo drivers,the unsung heroes of this revolution. These compact yet powerful components play an integral role in ensuring that every micro-adjustment translates into flawless execution. In this article, we will delve into the intricate mechanics of micro servo drivers, exploring their importance, functionality, and the pivotal role they play in unlocking the potential of modern engineering. Join us as we navigate thru the world of micro servo drivers, illuminating the pathways to precision that help shape the technology of tomorrow.

Table of Contents

- Exploring the Fundamentals of Micro servo Technology

- Key Features and Benefits of Micro Servo Drivers

- Integration Techniques for Enhanced Performance

- Best Practices for Selecting the Right Micro Servo Driver

- Q&A

- to sum up

Exploring the Fundamentals of Micro Servo Technology

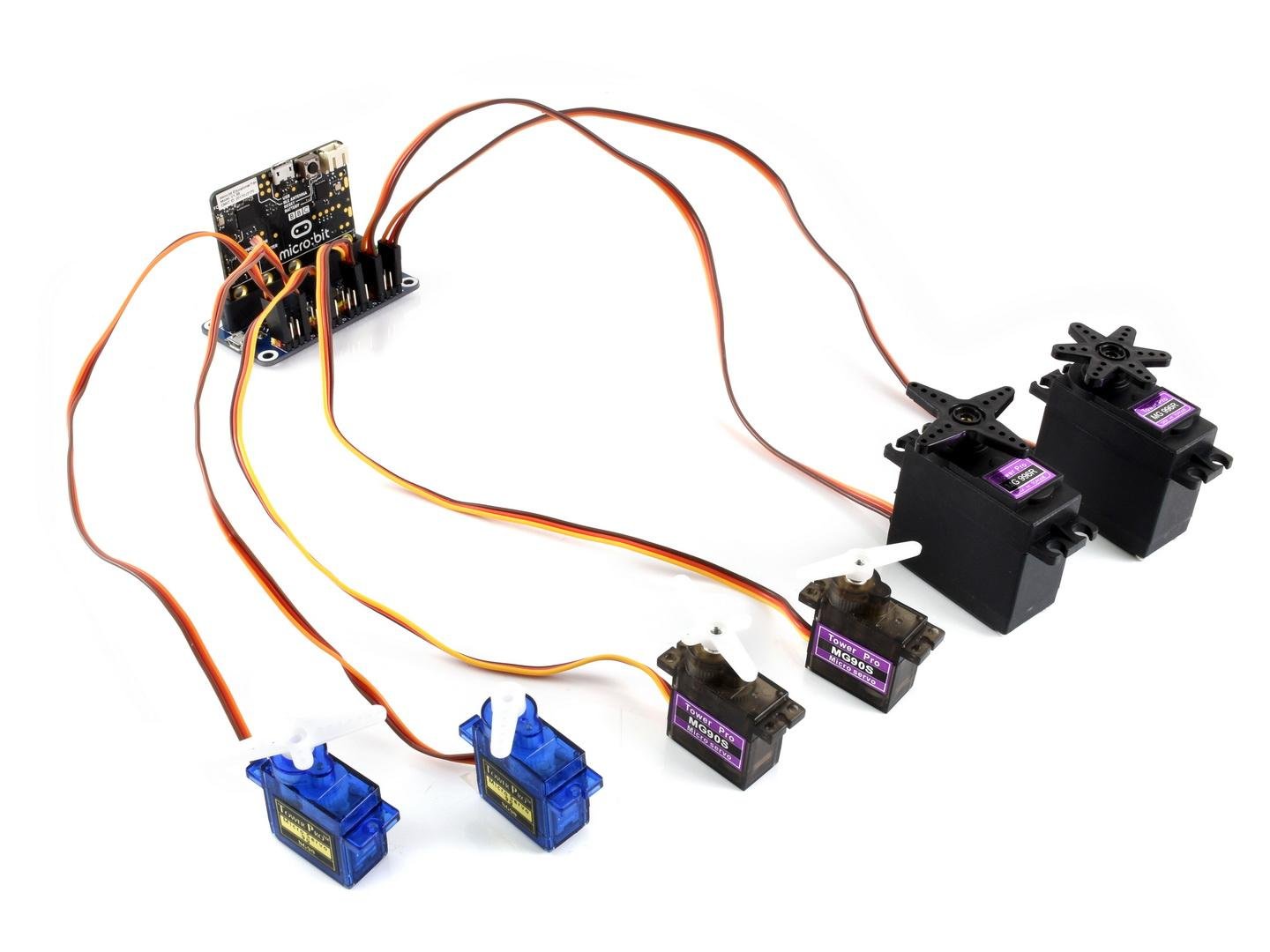

Micro servos are compact devices that are instrumental in achieving high precision movement in various applications, from robotics to remote control systems. Their design is based on a small motor connected to a feedback mechanism which allows for precise control of angular position. This feedback loop is crucial, as it enables the servo to make minute adjustments based on the input signals it receives. The ability to operate with minimal power while delivering accurate motion makes micro servos an effective choice in many DIY projects and professional applications alike.

To understand how micro servos function, we need to explore their components and the technology behind their operation. Key features include:

- Compact Size: Easily integrated into tight spaces.

- Ease of use: Simple to control via PWM signals.

- Cost-Effectiveness: Affordable options perfect for hobbyist projects.

- Versatility: Can be used in applications ranging from RC cars to camera gimbals.

Furthermore, the efficiency of micro servos heavily relies on their drivers, which play a pivotal role in controlling functionality. These drivers are responsible for interpreting input signals and converting them into the specific movements required by the servo motor. The types of drivers can vary depending on the request needs, ranging from basic ones suitable for simple tasks to advanced models capable of complex maneuvers. Here’s a brief comparison of some popular drivers:

| Driver Type | Control Method | Applications |

|---|---|---|

| Standard PWM Driver | PWM Signal | Basic Robotics |

| Analog Controller | Variable Voltage | RC Vehicles |

| digital Servo Driver | Digital Protocols | High Precision Needs |

Key Features and Benefits of Micro servo Drivers

Micro servo drivers are designed to optimize the performance of small servomotors, enhancing control and precision in various applications. These drivers boast a range of key features that make them indispensable in robotics,automation,and other precision tasks. Among them are:

- High Precision Control: Micro servo drivers provide accurate positioning with minimal delay, crucial for tasks requiring fine movements.

- Compact Size: Their small form factor makes them ideal for projects where space is limited, enabling seamless integration into compact systems.

- Low power Consumption: These drivers operate efficiently, reducing the energy footprint and extending battery life in portable applications.

Another significant advantage of micro servo drivers is their versatility across various environments and applications. They can be readily configured for diverse setups, from simple robotic arms to intricate automation systems. Key benefits include:

- Adaptability: Easy to program and configure, allowing use in multiple types of control systems.

- Robust Performance: Engineered to withstand challenging operating conditions, ensuring reliability in critical applications.

- cost-Effectiveness: Offering a balance of performance and affordability, making them accessible for both hobbyists and industrial applications.

the combination of these features and benefits positions micro servo drivers as vital components in achieving high-performance mechanical solutions. Here’s a swift summary of their standout attributes:

| Feature | Benefit |

|---|---|

| High Precision Control | Increases accuracy in movement and positioning |

| Compact Size | Facilitates integration into limited spaces |

| Low Power Consumption | Extends operational time for portable devices |

| Adaptability | Supports diverse applications and systems |

Integration Techniques for Enhanced performance

Integrating micro servo drivers with existing systems can significantly enhance the performance of various applications. By utilizing modular connectivity options, developers can seamlessly incorporate these drivers into robotics, automation, and even DIY projects. This versatility allows for a diverse range of configurations that can be customized to meet specific requirements. Key techniques to consider include:

- Serial Dialogue: Implementing RS232 or UART protocols for straightforward control and feedback.

- Analog Input Processing: Utilizing PWM signals for precise positioning and speed adjustments.

- Closed-Loop Control Systems: Integrating feedback mechanisms to fine-tune motion accuracy and reliability.

Moreover, leveraging advanced synchronization techniques can lead to smoother operations, especially in multi-servo setups.Techniques such as time division multiplexing (TDM) can be employed to manage multiple servo signals, ensuring that each driver receives its command precisely when needed. This results in minimized latency and enhances overall system responsiveness. Consider utilizing:

- Simultaneous Signal Processing: to coordinate multiple servos for complex motion profiles.

- Event-Driven Control: minimizing idle time by activating servos only when necessary.

- Priority Scheduling: Ensuring critical operations occur without delay.

Lastly, optimizing power management through integrated energy-efficient driver circuits can greatly improve the operational lifespan of your systems. Employing techniques such as dynamic voltage scaling and duty cycling can help conserve energy while providing consistent performance. A summarized comparison of potential power saving methods is illustrated below:

| Method | Benefit | Efficiency Gain |

|---|---|---|

| Dynamically Adjusted Voltage | Reduces energy consumption | Up to 30% |

| Duty Cycling | Extends battery life | 20-50% |

| Sleep Modes | minimizes power during inactivity | Up to 90% |

Best Practices for Selecting the Right Micro Servo Driver

Choosing the ideal micro servo driver requires careful consideration of several key factors to ensure that your application performs with maximum efficiency and reliability. First and foremost, understanding the specifications of your servo motor is crucial. Look for drivers that can accommodate the voltage and current ratings of your servos, as mismatched specifications can lead to underperformance or, worse, damage to your components. Ensure that the driver can support the torque requirements necessary for your specific project.

Next,evaluate the control features offered by the driver. Different projects may require varying levels of responsiveness and control options. Consider whether you need features like PWM (Pulse Width Modulation) control or feedback systems for precise positioning. Some micro servo drivers come with integrated ways to easily connect to microcontrollers, enhancing user experience and functionality. A table comparing common control features in various micro servo drivers can provide clarity:

| Driver model | PWM Control | Feedback Integration | Max Voltage (V) |

|---|---|---|---|

| Model A | Yes | No | 6 |

| Model B | Yes | Yes | 12 |

| Model C | No | No | 5 |

Lastly, consider the additional features and compatibility of the driver with your existing components. Some micro servo drivers offer advanced capabilities, such as built-in accelerometers or configurable settings through software. These features can significantly enhance your project’s functionality. Additionally, research user reviews and technical support availability from the manufacturer; a well-supported product can save you time and headaches during the progress process. Prioritizing these elements will help ensure a triumphant application of your micro servo drivers.

Q&A

Unlocking Precision: The Role of Micro servo Drivers Explained – Q&A

Q: What exactly is a micro servo driver?

A: A micro servo driver is a specialized electronic circuit designed to control the movement of micro servos. Unlike traditional servo controllers, micro servo drivers are compact, lightweight, and engineered for high precision, making them ideal for various applications, from robotics to hobbyist projects.

Q: How do micro servo drivers improve precision in movement?

A: Micro servo drivers enhance precision by employing advanced control algorithms that regulate power distribution and signal response.This allows for finer adjustments and smoother operation, ensuring that each movement of the servo is accurate and repeatable. Whether it’s adjusting the angle of a robotic arm or steering a model airplane,the driver optimizes performance for high fidelity.

Q: Can you explain the technology behind these drivers?

A: At the core, micro servo drivers utilize Pulse Width Modulation (PWM) to deliver accurate control signals to servos. They convert input signals into specific output movements based on pulse duration, allowing users to set precise angles of rotation. Additionally, some drivers include feedback loops and sensors that monitor performance, adapting to ensure that movements remain as accurate as possible.

Q: What types of projects benefit most from using micro servo drivers?

A: Micro servo drivers are highly versatile and can enhance a wide array of projects. They are commonly used in robotics, drone flight control, automated systems, animatronics, and even educational kits. Essentially, any project requiring precise angular positioning or repetitive movements stands to benefit from these advanced drivers.Q: Are micro servo drivers user-kind for beginners?

A: Yes! Many micro servo drivers are designed with ease of use in mind. They often come with extensive documentation,sample codes,and compatibility with popular platforms like Arduino. This accessibility allows beginners to dive into projects without a steep learning curve, making it an excellent entry point into the world of electronics and robotics.

Q: What should I consider when choosing a micro servo driver?

A: When selecting a micro servo driver, consider factors such as the voltage and current ratings, the number of servos it can control simultaneously, and its compatibility with your existing hardware. Additionally,assess the features that may enhance your project,such as built-in sensors,programmable settings,or support for various communication protocols.

Q: Are there limitations to micro servo drivers?

A: While micro servo drivers are powerful, they do have limitations.They are typically effective for low-to-medium load applications; heavy-duty tasks may require more robust solutions.Additionally, complex movements or rapid repositioning may need finely tuned programming to avoid overshoot or delays.Q: What future advancements do you foresee in micro servo driver technology?

A: The future of micro servo driver technology is promising, likely incorporating artificial intelligence and machine learning to further enhance control capabilities. This could lead to systems capable of adaptive response and improved efficiency. Additionally, advancements in materials and miniaturization may pave the way for even smaller, more powerful drivers that can be integrated into an expanding range of applications.Q: How can someone get started with micro servo drivers?

A: Getting started with micro servo drivers requires a basic understanding of electronics and programming. A good first step is to gather some basic components, such as a micro servo, a driver, a microcontroller (like Arduino), and connecting wires. Numerous online tutorials and communities are available that provide step-by-step guides and project ideas to help beginners kick off their journeys in precision control.

micro servo drivers are at the forefront of precision in movement control,bridging the gap between intricate design and functionality while inviting enthusiasts and professionals alike to explore endless possibilities in their projects.

In Conclusion

As we draw the curtain on our exploration of micro servo drivers, it’s clear that these compact components are the unsung heroes of precision engineering. From robotics to model aircraft, their ability to provide nuanced control makes them indispensable in a myriad of applications. Understanding their mechanics not only enhances our thankfulness of modern technology but also inspires innovation in design and function. As we continue to unlock new possibilities with micro servo drivers, one thing remains certain: the pursuit of precision is a journey that constantly propels us forward into the future. Whether you’re a seasoned engineer or a curious hobbyist, the world of micro servo drivers is one that promises to expand with every turn of the screw. So, let us celebrate this miniature marvel and look forward to the advancements that lie ahead.