Exploring Low-voltage DC Servo Drivers: Precision unleashed

In an age where precision reigns supreme in the world of automation, the spotlight is cast on a remarkable yet oft-overlooked component: the low-voltage DC servo driver. These sophisticated devices serve as the heartbeat of complex machinery, translating intricate commands into seamless motion with unparalleled accuracy. As industries evolve, the demand for efficiency and precision intensifies, making the exploration of low-voltage DC servo drivers not merely a technical inquiry but a journey into the essence of modern engineering.

This article delves into the world of low-voltage DC servo drivers, uncovering their mechanics, advantages, and the pivotal role they play in applications ranging from robotics to aerospace. By examining their functionality and the innovations driving their development, we aim to highlight how these drivers harness the potential of low-voltage operations to deliver extraordinary performance. Join us as we navigate this interesting domain where precision meets power, and discover how low-voltage DC servo drivers are shaping the future of automation.

Table of Contents

- Understanding the Mechanics of Low-Voltage DC Servo Drivers

- Enhancing Precision and Control in Industrial Applications

- Best Practices for Selecting the Right DC Servo Driver

- Future Trends Shaping Low-Voltage DC Servo Technology

- Q&A

- The Conclusion

Understanding the mechanics of Low-Voltage DC Servo Drivers

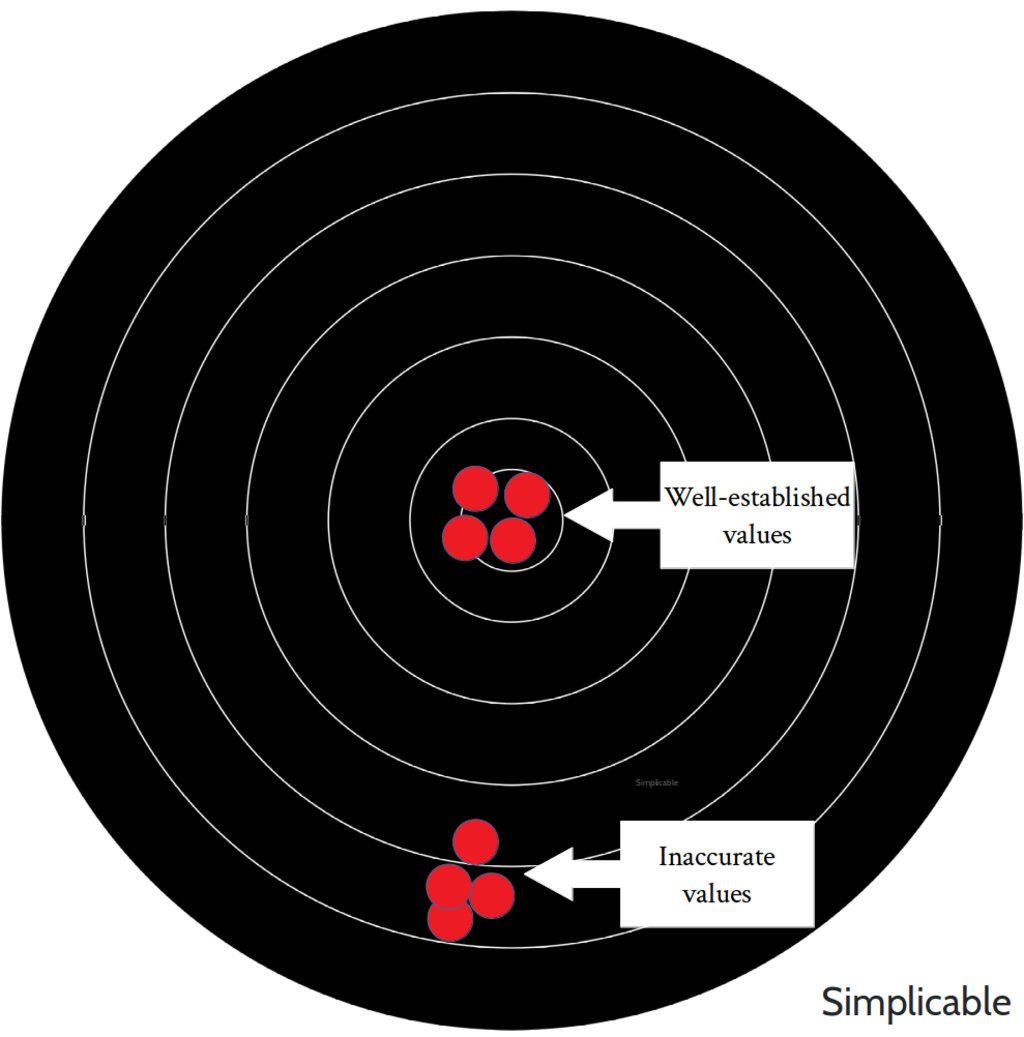

low-voltage DC servo drivers are sophisticated components that bridge the gap between commands from a control system and the mechanical motion of servo motors. They operate on the principle of managing electrical signals, converting them into mechanical energy with remarkable precision. The core mechanism involves closed-loop feedback systems, which continuously adjust the power supplied to the motor based on its actual position or speed in relation to the desired setpoint. This feedback loop ensures that the servo motor performs exactly as intended, maintaining accuracy even under varying load conditions.

One of the standout features of these drivers is their ability to operate at lower voltage levels while still delivering high performance. The use of MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) allows for efficient control of power, translating signals effectively without introducing notable losses. Furthermore, low-voltage operation reduces safety risks and enables integration with sensitive electronic components. Key components of low-voltage DC servo drivers include:

- Pulse Width Modulation (PWM): Controls speed and torque variably.

- Current Feedback Circuits: Protect against overheating and overcurrent.

- Digital Signal Processors (DSPs): Enhance response times and control accuracy.

The modular design of these servo drivers also enables easier customization, allowing engineers to tailor the control algorithms to suit specific applications. Integrating low-voltage DC servo drivers into existing systems can yield significant benefits, highlighted in the following table:

| Benefit | Description |

|---|---|

| Increased Efficiency | Lower energy consumption, prolonging battery life in portable applications. |

| Compact Design | Enables the development of smaller, lighter machines without sacrificing power. |

| Enhanced Precision | Achieves tighter tolerances in motion control for various engineering applications. |

Enhancing Precision and Control in Industrial Applications

In the realm of industrial automation, low-voltage DC servo drivers have emerged as innovative solutions that redefine the standards of precision and control. These drivers are adept at providing the fine-tuning necessary for various applications, ensuring that even the most intricate movements can be accurately executed. By employing advanced feedback mechanisms,low-voltage DC servo drivers can make real-time adjustments to speed and position,significantly enhancing the efficacy of machinery and equipment.

Key features inherent in these drivers underline their capability to optimize operational efficiency:

- High Resolution Feedback: Enabling precise tracking and position control.

- Rapid Response Times: Ensuring that adjustments occur within milliseconds for seamless operation.

- Compact Design: Allowing for easy integration in limited spaces while maintaining performance.

The following table illustrates the distinction between traditional motor drivers and low-voltage DC servo drivers, highlighting the advancements in features and performance:

| Feature | Traditional Motor Drivers | Low-voltage DC Servo Drivers |

|---|---|---|

| Control Precision | Moderate | High |

| Response Time | Slower | Fast |

| Size | Larger | Compact |

| Energy Efficiency | Variable | Optimized |

Through these advancements, low-voltage DC servo drivers provide not just improved precision but also enhanced control over operational parameters.Industries that rely on automation can benefit significantly from using these advanced drivers, as they pave the way for smoother workflows, reduced downtime, and ultimately, increased productivity. The choice to implement low-voltage DC servo drivers is not merely a step toward modernization; it’s a transformative evolution in the way industrial processes are executed.

Best Practices for Selecting the Right DC Servo Driver

Choosing the perfect DC servo driver involves a careful assessment of various factors that can significantly influence the performance and efficiency of your application.First and foremost, consider the current rating and voltage compatibility of the driver to ensure it meets the specifications of your chosen servo motor.Surge protection and thermal performance are additional attributes worth evaluating, as they can prevent potential damage and enhance longevity of the driver.Be sure to select a driver that matches or exceeds the power requirements of your system.

Next, examine the control features offered by different drivers. Drivers equipped with advanced control algorithms, such as PID control or feedforward control, can vastly improve responsiveness and precision. Compatibility with various control formats (e.g., PWM, analog voltage, or digital interaction protocols) is also crucial. Furthermore, software support and programming ease are essential aspects that can save time and reduce complications during integration.

Lastly, you should assess the cost-effectiveness of each option.While higher-priced models may offer more features or better performance, it’s significant to align your choice with the specific requirements of your project to avoid overspending. Creating a comparison table can be an effective method to visualize the attributes of different models:

| Driver Model | Current Rating (A) | Control Type | Price ($) |

|---|---|---|---|

| Model A | 5 | PID | 200 |

| Model B | 10 | Feedforward | 350 |

| Model C | 7 | PWM | 275 |

future Trends Shaping Low-Voltage DC Servo Technology

The landscape of low-voltage DC servo technology is on the brink of significant evolution, driven by trends that promise to enhance precision, control, and application versatility. As industries continue to automate their processes, the demand for highly responsive servo systems is skyrocketing. One of the key trends is the integration of machine learning and artificial intelligence (AI) into servo control systems. This evolution allows for enhanced predictive capabilities and real-time adjustments, pushing the boundaries of precision and efficiency in motion control.

Additionally, the advancement in smart materials and microelectronics is paving the way for more compact and energy-efficient solutions. These innovations facilitate the development of servos that not only perform better but also consume less power, which is crucial as sustainability becomes a core focus across various sectors.By incorporating materials that respond intelligently to external stimuli, manufacturers are able to design systems that optimize performance while minimizing energy usage.

Lastly, the adoption of IoT (Internet of things) technology in servo systems cannot be overlooked. By enabling connectivity and communication between devices, IoT is set to revolutionize how servo systems operate within larger automation frameworks.This connectivity allows for real-time monitoring and data analytics, empowering users to make informed decisions to enhance system reliability and performance. The combination of these future trends will undoubtedly shape the next generation of low-voltage DC servo technology, leading to unprecedented levels of precision and automation.

Q&A

Q&A: Exploring Low-Voltage DC Servo Drivers: precision Unleashed

Q1: What exactly are low-voltage DC servo drivers, and what role do they play in automation?

A1: Low-voltage DC servo drivers are electronic devices that control the motion and position of DC servo motors. They convert input commands into precise control signals that instruct the motor on speed, direction, and torque.In the realm of automation, these drivers are essential for applications requiring high precision and responsiveness, such as robotics, CNC machines, and various manufacturing processes.

Q2: What advantages do low-voltage DC servo drivers offer compared to traditional drive systems?

A2: Low-voltage DC servo drivers present several advantages, including improved efficiency, lower power consumption, and reduced heat generation. Their compact size and lightweight design also contribute to overall system integration, making them ideal for applications where space is at a premium. Additionally, they provide finer control over motor movements, allowing for enhanced performance and accuracy.

Q3: Can you elaborate on the concept of “precision unleashed”? What does this mean for industries using servo technology?

A3: “Precision unleashed” encapsulates the idea that low-voltage DC servo drivers enable unparalleled accuracy and control in motion applications. For industries leveraging this technology, it translates to achieving higher product quality, enhanced repeatability, and the ability to perform complex tasks with ease. This newfound precision not only optimizes production processes but can also lead to innovative designs and techniques that were previously unfeasible.

Q4: Are there specific applications where low-voltage DC servo drivers shine the most?

A4: Absolutely! Low-voltage DC servo drivers are particularly favorable in fields such as robotics (for precise manipulation tasks), automation (in assembly lines and material handling), aerospace (for control surfaces and actuation systems), and medical devices (for accurate positioning in surgical instruments). Their adaptability makes them suitable for any application that demands high precision and reliability.

Q5: What are some considerations engineers should keep in mind when selecting low-voltage DC servo drivers?

A5: Engineers should assess factors such as voltage and current ratings, control methods (such as PWM or analog inputs), and compatibility with existing systems. It’s also important to consider the environment in which the motors and drivers will operate, including temperature, humidity, and vibration levels.Moreover, examining the feedback mechanism (like encoders) and how it integrates with the driver can significantly influence performance outcomes.

Q6: What future developments can we expect in the realm of low-voltage DC servo drivers?

A6: The future promises exciting advancements, including the integration of IoT capabilities for remote monitoring and control, enhanced algorithms for better performance under various load conditions, and improvements in power management to further reduce energy consumption. As technology progresses, we may also witness the emergence of more compact designs and affordable options, making them accessible to an even broader range of industries and applications.

—

Q7: how can companies effectively integrate low-voltage DC servo drivers into their existing manufacturing systems?

A7: Effective integration begins with a thorough analysis of current workflows and machinery. Companies should invest in training their workforce to understand the new technology and its capabilities. Collaborating with manufacturers to customize driver and motor combinations to fit particular use cases ensures seamless operation. Testing new setups in controlled environments before full-scale deployment can also mitigate challenges and facilitate a smoother transition.

This Q&A aims to provide a nuanced overview of low-voltage DC servo drivers and their impact across various sectors, emphasizing their role in harnessing precision and pushing the boundaries of automated systems.

The Conclusion

As we draw the curtain on our exploration of low-voltage DC servo drivers, it becomes evident that these unassuming components are far from mere footnotes in the world of automation. They embody the delicate dance between precision and power, seamlessly transforming commands into motion with an accuracy that propels innovation forward. With applications spanning robotics,manufacturing,and beyond,the importance of these drivers cannot be overstated.

By embracing the nuances of low-voltage operation, engineers and designers unlock a realm of possibilities that not only enhances performance but also fosters energy efficiency and system longevity. As technology continues to evolve, the role of DC servo drivers in shaping the future of automated systems will only grow more prominent.

In this journey through the intricacies of circuitry and control, we’ve glimpsed the potential that lies within these devices. As industries strive for greater precision and efficiency, the spotlight shines brightly on the pivotal role that low-voltage DC servo drivers will play. The precision is unleashed, and the quest for innovation continues—driven, quite literally, by these remarkable components.Thank you for joining us in this exploration; the future is yours to navigate.