In the ever-evolving landscape of automation and robotics,the quest for precision control has never been more paramount. Low-voltage direct current (DC) servo drivers have emerged as pivotal components in this journey, seamlessly transforming electrical energy into finely-tuned motion. These sophisticated devices not only facilitate precise positioning and velocity control but also enhance the efficiency and responsiveness of a myriad of applications, from industrial machinery to consumer electronics.In this article, we will delve into the intricate world of low-voltage DC servo drivers, exploring their basic principles, key advantages, and the latest innovations shaping the future of motion control technology. Join us as we uncover how these compact yet powerful solutions are redefining the benchmarks for performance and control in diverse engineering fields.

Table of Contents

- Understanding the Fundamentals of Low-voltage DC Servo Drivers

- Key Advantages of Precision Control in Modern Applications

- Choosing the Right Low-Voltage DC Servo Driver for your Needs

- Best Practices for Optimizing Performance and Efficiency

- Q&A

- Future Outlook

Understanding the Fundamentals of Low-Voltage DC Servo Drivers

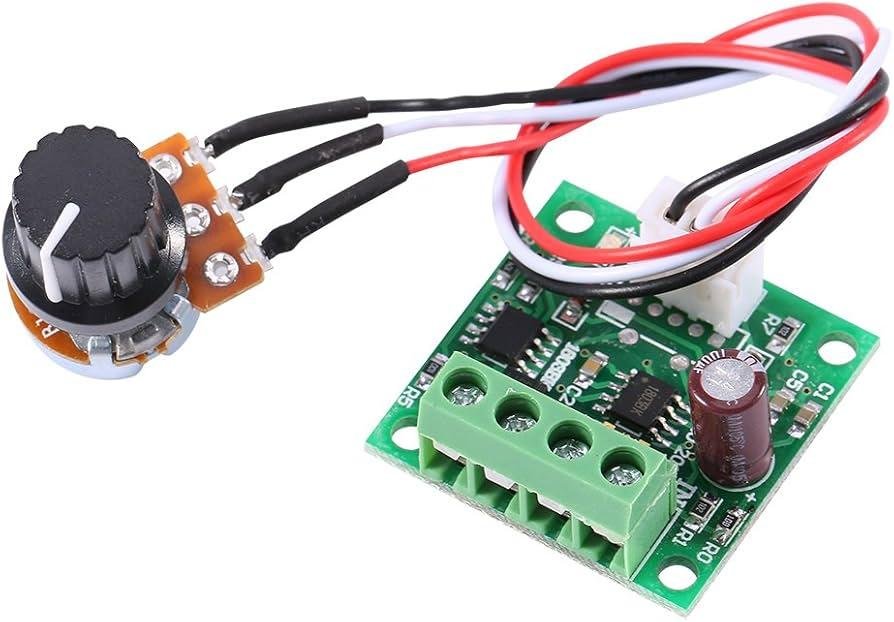

Low-voltage DC servo drivers are essential components in the realm of precision motion control. They operate by regulating the voltage supplied to the motor, ensuring that it performs optimally according to the commands it receives. The primary function of these drivers is to convert input signals—often from an encoder or a control system—into the appropriate motor actions. This process enables a highly responsive and efficient operation,making them ideal for applications such as robotics,CNC machinery,and automated systems.

Several key features define low-voltage DC servo drivers, enhancing their functionality and reliability in diverse applications. These include:

- High Efficiency: Operating at lower voltages increases safety and reduces energy consumption.

- Precision Control: They provide accurate positioning and speed control,critical for applications requiring fine-tuned movements.

- Compact Design: Smaller size and weight allow for easier integration into tight spaces or portable systems.

- Feedback Mechanisms: Many models include feedback systems to monitor real-time performance and make adjustments as needed.

The versatility of low-voltage DC servo drivers is further highlighted by their compatibility with various control systems. Below is a concise comparison of diffrent control methods commonly used:

| Control Method | Advantages | Disadvantages |

|---|---|---|

| Open Loop Control | Simplicity,Low Cost | No feedback; less accuracy |

| Closed Loop Control | High precision; Real-time adjustment | More complex setup; Higher cost |

| PID Control | Well-regulated output; Versatile | Requires tuning; Can oscillate if not properly set |

Key Advantages of Precision Control in Modern Applications

Precision control stands at the forefront of modern technological advancements,enabling unprecedented levels of accuracy in a variety of applications. With the integration of low-voltage DC servo drivers, industries such as robotics, manufacturing, and automation are experiencing enhanced performance metrics. These systems allow for intricate movements and responsive adjustments,which significantly improve overall efficiency and effectiveness in processes. By utilizing precision control, operators can achieve outcomes that are not only faster but also more reliable.

Another notable advantage of precision control lies in its contribution to reducing operational costs. By increasing the accuracy of movements and minimizing waste, companies can see substantial savings in both time and resources. moreover, lower energy consumption when using low-voltage DC servo drivers contributes to sustainable practices, appealing to environmentally conscious businesses. The resultant increase in productivity directly impacts the bottom line,making precision control an essential component in competitive industries.

In addition to enhancing efficiency and reducing costs, precision control also plays a critical role in safety. With precise movements and real-time adjustments made possible by advanced drivers,potential hazards can be significantly mitigated. Operators have greater visibility and control over machinery, enabling swift responses to unforeseen circumstances. This leads to improved workplace safety and higher quality standards, fostering a culture of continuous improvement and innovation within organizations.

Choosing the Right Low-Voltage DC Servo Driver for Your Needs

When selecting a low-voltage DC servo driver, it’s essential to evaluate several critical factors to ensure compatibility with your specific application. Consider the motor type that you intend to drive, as different motors require varying driver specifications. You’ll want to align voltage ratings and current ratings to prevent underperformance or damage. Additionally, look for drivers that provide sufficient control modes such as velocity, torque, or position control, depending on your operational needs.

Another aspect to intentional is the environment in which the driver will operate. If your application demands high reliability, consider drivers with robust detection features and protection mechanisms. For example, drivers that include overcurrent protection, overvoltage protection, and thermal management features can significantly enhance durability and longevity. Furthermore, compatibility with interaction protocols such as CAN, RS-485, or Ethernet should also be assessed, especially if integration with other systems or devices is necessary.

Lastly, ease of integration is paramount. Look for low-voltage DC servo drivers that offer extensive documentation and have a supportive user community for troubleshooting. Pay attention to the size and mounting options to ensure that the driver fits into your existing system without requiring extensive modifications. A comparison table might be beneficial for a side-by-side review of potential options:

| Driver Model | Voltage Range | Max Current | Control Modes | Protection Features |

|---|---|---|---|---|

| Model A | 12-24V | 10A | Torque, Speed | Overcurrent, thermal |

| Model B | 5-15V | 5A | Position, Torque | Overvoltage, Short Circuit |

| Model C | 24-48V | 15A | Position, Speed | Overcurrent, Thermal, Overvoltage |

Best Practices for Optimizing Performance and Efficiency

Optimizing performance and efficiency in low-voltage DC servo drivers involves a multi-faceted approach that combines mechanical, electronic, and software elements. One of the most effective strategies is to focus on motor tuning. Fine-tuning parameters such as PID values can significantly enhance response times and reduce overshoot. It’s essential to regularly monitor system performance and recalibrate these settings as necessary to maintain optimal operation.

Another critical aspect is the selection of the right power supply. The quality and characteristics of the power supply directly affect servo performance. Ensuring that the power supply meets the required voltage and current ratings can help in minimizing fluctuations that may lead to performance degradation.It’s beneficial to utilize power supplies with features like current limiting, short-circuit protection, and noise filtering. A well-chosen power supply can help maintain consistent performance even under varying load conditions.

| Power Supply Feature | Description |

|---|---|

| Current Limiting | Prevents excessive current from damaging the driver or motor. |

| Short-Circuit Protection | Safeguards the system by cutting power in the event of a short. |

| Noise Filtering | Reduces electrical noise that can interfere with servo control signals. |

Additionally, leveraging advanced control algorithms can substantially boost efficiency. Techniques like feedforward control can predict system behavior and improve responsiveness by adjusting commands in advance. Implementing motion planning strategies can also reduce unneeded movements, leading to less wear and tear. Lastly, regularly updating firmware ensures that the driver utilizes the latest performance enhancements and bug fixes, maximizing operational efficiency in real-time applications.

Q&A

Q&A: Exploring Low-Voltage DC Servo Drivers in Precision Control

Q: What exactly are low-voltage DC servo drivers, and how do they function?

A: Low-voltage DC servo drivers are specialized electronic devices designed to control the motion of DC servo motors. They operate at lower voltage levels, typically below 60 volts, and regulate the speed, position, and torque of the motor with high precision.By adjusting the current provided to the motor coils based on feedback from position sensors,these drivers ensure that movements are accurate and repeatable,making them ideal for applications where precision is paramount.

Q: What are the primary applications for low-voltage DC servo drivers?

A: These drivers are widely used in various industries, including robotics, CNC machining, 3D printing, and automation systems. They serve in applications requiring precise control, such as steering systems in autonomous vehicles, print heads in 3D printers, and actuators in robotic arms. Their ability to deliver nuanced control at low voltages also makes them suitable for small-scale and portable devices.

Q: Why is precision control important in modern machinery?

A: Precision control is crucial becuase it directly impacts the efficiency, performance, and quality of the final product. In industries like electronics manufacturing or aerospace,even minute deviations can lead to significant issues. Low-voltage DC servo drivers help maintain tight tolerances and minimize errors, ensuring that machines operate reliably and safely.

Q: How do low-voltage DC servo drivers compare to other motor control systems?

A: compared to traditional AC drives or stepper motor systems, low-voltage DC servo drivers offer smoother operation and more precise control over motion. They can respond faster to changes in commands and deliver higher torque at lower speeds, which is essential for applications requiring fine adjustments. While stepper motors are simpler, they can be less efficient in maintaining precise positioning over time, especially under load.

Q: What are the key features to look for when choosing a low-voltage DC servo driver?

A: When selecting a low-voltage DC servo driver,consider features such as feedback compatibility (e.g., encoders or resolvers), control methods (like PWM or voltage control), communication interfaces (CAN, RS-232, or Ethernet), and safety features (such as overcurrent protection). Additionally,evaluating the driver’s efficiency rating and temperature range will help ensure it meets your specific application needs.

Q: Can you elaborate on the benefits of using low voltage in these servo drivers?

A: Operating at low voltages can enhance safety, reduce the risk of electrical shock, and lower energy costs. Low-voltage servo drivers generate less heat, which improves reliability and extends the lifespan of both the driver and the motor. This can also lead to smaller and lighter systems,making them more suitable for portable applications with space constraints.

Q: What should engineers consider when integrating these drivers into their systems?

A: Engineers should take into account factors such as the compatibility of the servo driver with the existing control system, the specific performance requirements of their application, and the overall system architecture. It’s also vital to assess the availability of technical support and the manufacturer’s reputation for reliability and innovation in driver technology.

Q: Are there any emerging trends in the field of low-voltage DC servo drivers?

A: Yes, there are several trends shaping the future of low-voltage DC servo drivers.These include the integration of advanced algorithms for better control, the move towards more compact and efficient designs, and the increasing use of IoT-enabled devices for remote monitoring and adjustments. Additionally,as industries push for greater sustainability,manufacturers are experimenting with improved energy-efficient designs that align with eco-pleasant practices.

Q: How do you see the future of precision control evolving with these technologies?

A: The future of precision control will likely see greater integration of artificial intelligence and machine learning, allowing for even more adaptive and responsive systems. As automation continues to expand across various sectors, low-voltage DC servo drivers will play a pivotal role in enhancing performance, responsiveness, and efficiency, facilitating the advancement of smarter and more capable machines.

Future Outlook

the world of low-voltage DC servo drivers reveals a captivating interplay between precision, efficiency, and innovation. As we’ve explored, these cutting-edge devices are not just mere components in a machine; they are the unsung heroes that enable a wide array of applications, from robotics to automation systems, all while ensuring meticulous control and responsiveness. As technology continues to evolve, the importance of precise control in various sectors will only increase, paving the way for even more refined and sophisticated solutions. Embracing advancements in low-voltage DC servo technology not only enhances performance but also sets the stage for a future where automation and control blend seamlessly, driving us towards ever-greater heights of possibility. We invite you to reflect on the insights shared here and consider how these drivers might influence your own endeavors in the realm of engineering and beyond. Thank you for joining us on this journey into precision control; the possibilities are just beginning.