In an era where innovation and efficiency dominate the landscape of technological advancement, the spotlight is increasingly turning towards low-voltage solutions that promise to reshape industries and optimize performance. At the forefront of this transformation is the revolutionary Dervo Driver—a cutting-edge device designed to redefine how we harness energy and control power systems. As businesses and engineers seek ways to enhance operational efficiency while minimizing costs, the Dervo Driver emerges as a beacon of potential, offering a sophisticated approach that melds sustainability with high function. In this article, we will delve into the intricacies of mastering efficiency through the low-voltage Dervo Driver, exploring its design, applications, and the profound impact it is set to have on the future of automation and energy management. Join us as we uncover the nuances of this engaging innovation, paving the way for a more efficient tomorrow.

Table of Contents

- Unleashing Power: Understanding the Low-Voltage Dervo Driver Technology

- maximizing Performance: Key Advantages of Low-Voltage Integration

- Practical Deployment: Best Practices for Implementing Dervo Drivers

- Future trends: Innovations Shaping the Low-Voltage Landscape

- Q&A

- Final Thoughts

Unleashing Power: Understanding the Low-Voltage Dervo Driver Technology

The evolution of driver technology has reached an exciting juncture with the advent of low-voltage Dervo driver systems. These innovative devices not only promise enhanced performance and efficiency but also contribute to a more sustainable and eco-kind operation of electrical devices. Low-voltage Dervo drivers are designed to handle lower energy demands while maintaining outstanding performance levels, transforming the landscape of electrical engineering and application.

Embracing this technology unlocks a multitude of advantages, including:

- Reduced Energy Consumption: Operating at lower voltages significantly cuts energy usage, leading to reduced operational costs.

- Minimized Heat Generation: Lower voltage environments produce less heat, improving safety and lifespan of components.

- Versatile Applications: Ideal for a wide range of devices from home appliances to industrial machinery, promoting widespread adoption.

A critical aspect of low-voltage Dervo driver technology lies in its adaptability. This means that manufacturers can design products that not only comply with stringent energy regulations but also leverage smart controls for optimized performance. Moreover, as industries pivot toward greener practices, integrating these drivers into existing systems becomes increasingly essential.The future of electrical engineering is undoubtedly shining, defined by the efficiency and sustainability offered by low-voltage solutions.

Maximizing Performance: Key Advantages of Low-Voltage Integration

Integrating low-voltage systems facilitates enhanced performance across various applications, particularly in the realm of drivetrains.By operating at lower voltages,devices reduce energy loss,which translates into greater efficiency and lower operational costs. Consequently,industries are reaping several advantages:

- Energy Efficiency: Lower voltage systems consume significantly less power,thereby minimizing electrical waste.

- Thermal Management: reduced heat generation allows for the design of more compact systems,offering flexibility in space-constrained environments.

- Improved Safety: Working with lower voltages inherently lowers the risk of electrical shock, making systems safer for operators and maintenance personnel.

Moreover, low-voltage integration promotes advanced communication protocols within devices. With enhanced data transfer capabilities, systems can now operate and communicate with other devices in real-time, leading to smarter and more responsive operations. Here are additional advantages to consider:

| Feature | Benefit |

|---|---|

| modularity | facilitates easy upgrades and customization of systems |

| Longer Lifespan | Lower stress on components enhances durability |

| Cost-effective Maintenance | Reduced wear and lower energy costs lead to fewer repairs |

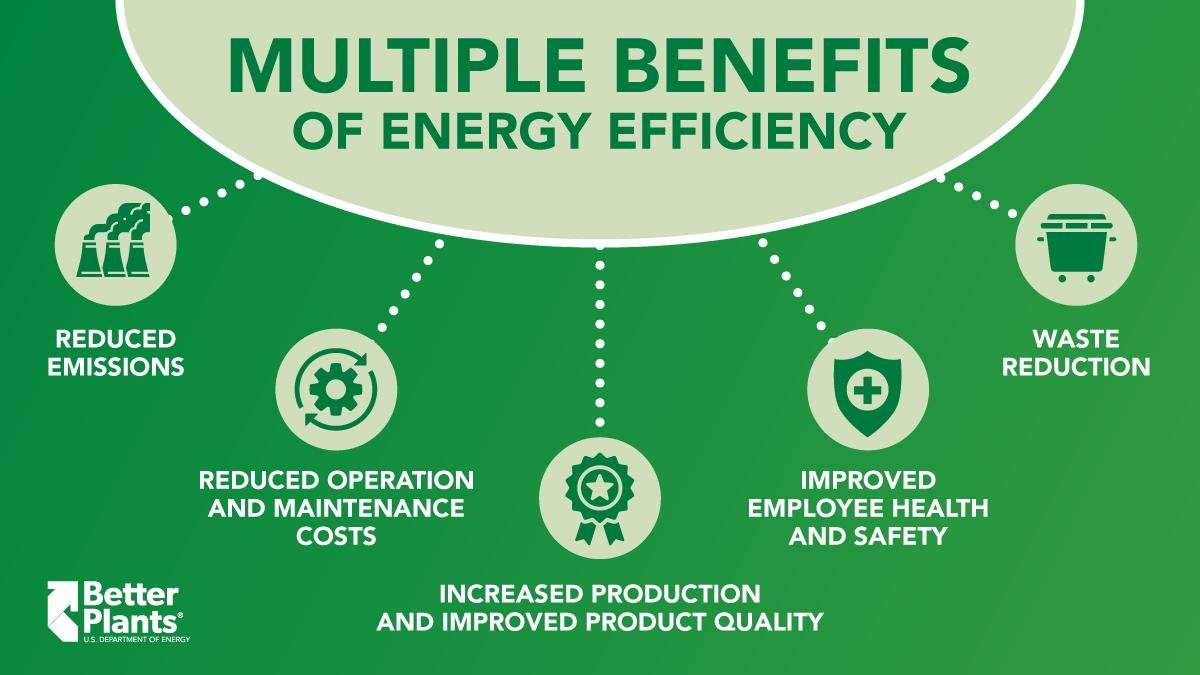

Additionally,the environmental impact of low-voltage integration is noteworthy. As industries emphasize sustainability, transitioning to low-voltage systems can contribute to a greener footprint. The following points highlight the ecological benefits:

- Lower Carbon Emissions: Reduced power consumption leads to less strain on power generation, translating to lower carbon footprints.

- Recyclable Components: Many low-voltage systems are designed with recyclable materials, further supporting eco-friendly initiatives.

- Compliance with Regulations: Adopting low-voltage solutions helps in meeting stringent regulations regarding energy efficiency and emissions.

Practical deployment: Best Practices for Implementing Dervo Drivers

When considering the deployment of Dervo drivers, it’s essential to establish a systematic approach that promotes efficiency and reliability. Start by conducting a thorough evaluation of your existing systems and understanding the specific requirements of your application. This initial assessment is crucial as it allows for the identification of potential challenges and opportunities wherein Dervo drivers can optimize operations. Engaging with stakeholders during this phase ensures that all needs are addressed, leading to a more integrated implementation process.

The next step involves meticulous planning and configuration. It is vital to consider the following best practices to streamline the integration of Dervo drivers:

- Standardization: Maintain uniformity in coding and documentation.This makes troubleshooting and future upgrades more manageable.

- Testing: Prior to deployment, conduct rigorous testing in a controlled surroundings to identify any performance issues.

- Training: Equip your team with proper training on the new technology to ensure thay are well-versed in handling the system effectively.

Lastly, establishing a robust monitoring and support system is vital for long-term success. Setting up real-time monitoring tools helps in tracking performance and identifying any anomalies before they escalate into major issues. Additionally, creating a feedback loop with end-users can provide valuable insights for continuous enhancement. Consider maintaining a resource hub for troubleshooting tips and maintenance guidelines, as well as scheduling regular system audits to ensure optimal functioning. Below is a simplistic representation of key monitoring metrics:

| Metric | Ideal Range | Action Required |

|---|---|---|

| Voltage Output | 12V – 24V | Adjust settings if outside range |

| Operating Temperature | 0°C – 70°C | Ensure adequate cooling |

| Performance Efficiency | 85% and above | Review operational parameters |

Future Trends: Innovations Shaping the Low-Voltage Landscape

As the demand for energy efficiency escalates, low-voltage technology is evolving at a remarkable pace. The advent of smart systems is pushing boundaries by integrating advanced machine learning and AI algorithms directly into low-voltage drives. These innovations allow for continuous optimization of performance, resulting in greater energy savings and reduced operational costs. With predictive maintenance becoming standard, operators can now foresee potential issues before they disrupt production, thereby minimizing downtime and enhancing overall system reliability.

Along with smart technologies, the emergence of plug-and-play solutions is simplifying installations and reducing the entry barrier for smaller businesses to adopt low-voltage drivers. Such innovations are characterized by their user-friendly design,enabling speedy deployment without needing specialized technical expertise. Benefits of these solutions include:

- Scalability: Easily integrated into existing systems.

- cost-effectiveness: Reduces labor and installation costs.

- Flexibility: Adaptable to various industrial applications.

The industry is also moving toward a greater emphasis on sustainable practices, propelled by regulatory demands and environmental considerations. Manufacturers are now evaluating their products through a sustainability lens, focusing on the lifecycle impact of low-voltage drivers. This shift is resulting in the development of energy-efficient materials and components which enhance performance while reducing waste. Below is a table summarizing key eco-innovations in the low-voltage sector:

| Innovation | Description |

|---|---|

| Eco-friendly Materials | Using biodegradable and recyclable components. |

| Energy Harvesting | Integrating renewable energy sources into powering systems. |

| Smart Sensors | Monitoring energy consumption in real-time for optimized usage. |

Q&A

Q&A: Mastering Efficiency: the Low-Voltage dervo driver Revolution

Q1: What is the Low-Voltage Dervo Driver, and why is it considered revolutionary?

A1: The Low-Voltage Dervo Driver is an innovative electrical component designed to operate efficiently at lower voltage levels, resulting in reduced energy consumption and enhanced performance for various applications. Its revolutionary aspect lies in its ability to maximize efficiency while minimizing heat generation and power loss, setting a new benchmark for electrical drivers in industrial and commercial settings.

Q2: how does the Low-Voltage Dervo Driver enhance efficiency compared to traditional drivers?

A2: Traditional drivers often operate at higher voltage levels, leading to increased energy waste and thermal inefficiencies. In contrast,Low-Voltage Dervo Drivers utilize advanced materials and smart technology to deliver superior performance with lower power requirements. This results in decreased operational costs, longer equipment life, and a smaller carbon footprint.

Q3: What are some practical applications of the Low-Voltage dervo Driver?

A3: Low-Voltage Dervo Drivers are versatile and can be integrated into various applications, including robotics, HVAC systems, electric vehicles, and renewable energy sources.Their efficiency makes them particularly suitable for environments where energy conservation is crucial, such as in sustainable building designs and automated manufacturing processes.

Q4: Can you explain how the design of the Dervo Driver contributes to its performance?

A4: The design of the Dervo Driver incorporates cutting-edge semiconductor technology that optimizes power conversion,along with advanced thermal management solutions that keep components cool even during heavy use. Additionally,smaller,more efficient designs allow for lightweight implementation,which is essential in applications where space and weight are critical factors.

Q5: What challenges does the Low-Voltage Dervo Driver aim to address in the current market?

A5: The Low-Voltage Dervo Driver addresses several challenges, such as energy inefficiency, high operational costs, and environmental concerns related to energy production and consumption. By providing a solution that reduces energy usage and heat waste, the Dervo Driver not only enhances performance but also supports the growing demand for sustainable and eco-friendly technology in various industries.

Q6: How can businesses transition to using Low-Voltage Dervo Drivers?

A6: Transitioning to Low-Voltage Dervo Drivers involves assessing current systems for compatibility, familiarizing engineering teams with the new technology, and gradually integrating the drivers into existing applications. Many manufacturers offer support services to assist in the transition, including training sessions and customized implementation plans to ensure a smooth adoption process.

Q7: What does the future hold for the Low-Voltage dervo Driver and its technology?

A7: The future of the Low-Voltage Dervo Driver technology looks promising, with continuous research and development paving the way for even more efficient and compact designs. As industries increasingly prioritize sustainability, we can expect widespread adoption of this technology, alongside innovations that further enhance its capability and integration with smart systems.

Q8: In what ways can individuals or organizations learn more about implementing this technology?

A8: Individuals and organizations can stay informed about the Low-Voltage Dervo Driver by attending industry conferences, subscribing to relevant publications, and participating in webinars hosted by experts in electrical engineering.Additionally, collaborating with manufacturers and technology providers will offer insider knowledge and guidance on best practices for implementing this revolutionary driver in various settings.

Final Thoughts

As we close the chapter on the “Low-Voltage Dervo Driver Revolution,” it’s clear that efficiency is no longer just a goal—it’s a necessity. With the advent of these innovative drivers, industries are poised to embrace a new era of performance that balances power consumption with output efficacy. The integration of low-voltage technology not only promises cost savings but also a substantial reduction in environmental impact,aligning with global sustainability goals.

As with any technological advancement, the path to mastery requires both understanding and adaptation. The Dervo driver serves as a beacon for engineers and manufacturers striving to navigate the evolving landscape of automation and control systems. Its potential to streamline workflows and optimize processes speaks volumes about the future of power management.

In the quest for efficiency, the Dervo driver is not just a tool; it is a catalyst for change, encouraging us to rethink how we design, implement, and interact with our energy systems. As we look ahead, embracing these innovations will be paramount to cultivating a more efficient, productive, and sustainable future. The question now becomes: How will you incorporate this revolutionary technology into your own journey toward efficiency?