In a world where technology continually pushes the boundaries of what is possible, the seemingly small yet mighty <a href="https://ydservo.com/product/amber-series-micro-servo-drives/” title=”Amber Series Micro Servo Drives”>micro servo has emerged as a pivotal player in a multitude of applications. From intricate robotic systems to delicate automation projects, these compact devices have the remarkable ability to provide precise movement adn <a href="https://ydservo.com/product/diamond-plus-series-pin-servo-drivers/” title=”Diamond Plus Series Pin Servo Drivers”>control. However,harnessing the full potential of micro servos requires more than just the right components—it demands a profound understanding of their drivers and the art of fine-tuning them. In this article, we delve into the intricate realm of micro servo driver control, exploring the principles and techniques that enable enthusiasts and professionals alike to unlock the precision required for optimal performance. Whether you’re a seasoned engineer or an eager hobbyist, join us on a journey to discover how the mastery of micro servo drivers can transform your projects, elevating them from the mundane to the unusual.

Table of Contents

- Exploring the Fundamentals of Micro Servo Technology

- Mastering Control algorithms for Enhanced Performance

- Fine-Tuning Signal Integrity and Power Management

- Practical Tips for Optimizing Micro Servo Applications

- Q&A

- Closing Remarks

Exploring the Fundamentals of Micro Servo Technology

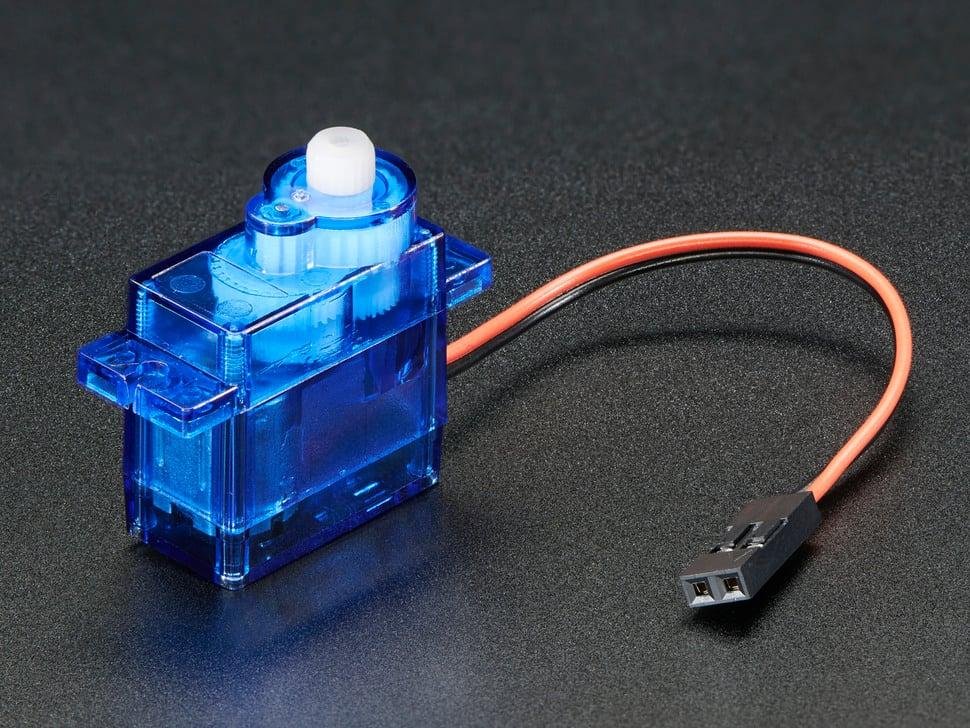

Micro servo technology has become a cornerstone in the realm of robotics and automation, offering an unparalleled blend of precision and control in compact systems. At the heart of this technology lies the ability to manipulate output position and rotational speed with incredible accuracy. Typically, micro servos are designed to achieve a range of motion between 0 and 180 degrees, making them ideal for applications that require fine-tuned adjustments, such as in robotic arms, camera gimbals, and even miniature drones.

Understanding the architecture of micro servos is crucial for effective driver control. Modern micro servos operate using pulse width modulation (PWM) signals, where the duration of the pulse determines the angular position of the servo arm. This necessitates a precise calibration of the signal frequency and width, which can be influenced by various factors including the load and operating temperature. Integrating effective feedback systems ensures that the servo responds accurately to commands while compensating for any deviations caused by external forces or system wear.

| Feature | Description |

|---|---|

| Torque | Typical torque ranges from 1.5 to 2.5 kg-cm for micro servos, suitable for lightweight applications. |

| Control Signal | PWM signal with a frequency of approximately 50Hz is commonly used for position control. |

| Power Supply | Generally operates between 4.8V and 6.0V,ensuring effective performance. |

Ultimately, the application of micro servo technology extends beyond traditional robotics. Industries such as photography, automation, and even consumer electronics leverage micro servos for tasks that demand reliability and precision. As we explore innovative driver control methods, we tap into the potential of these small yet robust components, creating solutions that not only meet but exceed our performance expectations in various engineering domains.

Mastering Control Algorithms for Enhanced Performance

In the realm of micro servo driver control, the mastery of control algorithms is pivotal to achieving optimal performance. These algorithms not only govern the movement of servos but also enhance the responsiveness and accuracy of the entire system.By integrating advanced algorithms such as PID (Proportional-Integral-Derivative), developers can fine-tune their control strategies to respond dynamically to varying load conditions. This adaptability ensures that even the most delicate applications, such as robotic arms or automated precision instruments, can operate with unparalleled smoothness and reliability.

Moreover, understanding the principles behind feedback control systems is crucial for developing effective servo drivers. A well-designed system should focus on a few key aspects:

- Stable Performance: Ensures that the system returns to equilibrium after disturbances.

- Minimal Overshoot: Reduces the risk of mechanical stress on components.

- Rapid Response Time: Enhances system agility for real-time applications.

By prioritizing these elements, engineers can create robust drivers that not only meet but exceed performance expectations.

To illustrate the influence of control algorithm settings, consider the following comparison of PID parameter configurations and their impact on system performance:

| PID Configuration | Response time | Overshoot | Stability |

|---|---|---|---|

| High P, Low I, low D | Fast | High | Moderate |

| Moderate P, Moderate I, High D | Moderate | Low | High |

| Low P, High I, Moderate D | Slow | Moderate | Moderate |

Ultimately, the key to unlocking the full potential of micro servo drivers lies in the careful calibration of these control algorithms. By experimenting with different settings and continuously refining their approach, engineers can ensure that their designs are capable of meeting the demands of any application with precision and finesse.

Fine-Tuning Signal Integrity and Power Management

To achieve optimal performance from micro servo drivers, meticulous attention to both signal integrity and power management is essential. Signal integrity ensures that the data transmitted to the servos maintains its quality, minimizing errors or distortions that could lead to erratic behavior. Key considerations include:

- PCB Design: Utilize short traces and proper routing to prevent signal degradation.

- Grounding: Implement a solid grounding strategy to reduce electromagnetic interference (EMI).

- Signal Filtering: apply appropriate filters to remove unwanted noise from control signals.

Power management plays a critical role in the reliability of micro servo drivers. Servos often draw varying amounts of current, especially under load, which can introduce voltage fluctuations. Effective strategies for managing power consumption include:

- Decoupling Capacitors: Place capacitors near the power pins of the servo drivers to stabilize voltage levels.

- Buck Converters: Utilize efficient converter circuits to regulate voltage and reduce power loss.

- Dynamic Power Scaling: Implement algorithms that dynamically adjust power requirements based on operational demands.

Integrating both signal integrity and power management techniques ensures that micro servo drivers operate under optimal conditions, maximizing their responsiveness and precision.A holistic approach to these aspects can be further illustrated in the following table:

| Technique | Description |

|---|---|

| Signal Shielding | Protects against external interference to enhance transmission quality. |

| Voltage Regulation | Maintains consistent voltage levels to ensure reliable servo operation. |

| Load Analysis | Evaluating the current requirements based on the application for efficient operation. |

Practical Tips for Optimizing Micro Servo Applications

To maximize the performance of micro servo applications, start by calibrating your servo correctly. Accurate calibration ensures that your servo performs optimally, reducing the risk of unnecessary strain or fluctuations during operation. This involves setting the neutral position and fine-tuning the range of motion. tools such as a potentiometer can assist in this process,allowing for precise adjustments. Remember,the more accurately you align the physical and electronic components,the smoother your applications will operate.

Another essential aspect to consider is the power supply. Micro servos require adequate voltage to function effectively, and fluctuations in power can lead to erratic behavior. Using a dedicated power source, such as regulated power supplies or battery packs designed for servos, can significantly enhance performance and longevity.Make sure to monitor the current requirements to avoid damage. Furthermore, implementing a decoupling capacitor near the servo can help stabilize voltage by filtering out noise, improving responsiveness.

experiment with control algorithms to find the best fit for your application. Whether you’re using pulse-width modulation (PWM) or more advanced techniques, the right algorithm can make a substantial difference in the precision of movement. Consider testing different control strategies, such as PID (Proportional, Integral, Derivative) control, which can provide smoother and more responsive motion. Hear’s a simple table to illustrate some common control methods:

| Control Method | Features | Best Use Cases |

|---|---|---|

| PWM | Simple, widely supported | Basic rotation tasks |

| PID Control | Fine-tuned, stable | precision applications |

| Servo Library Functions | Easy setup, interactive | Prototyping, educational projects |

Q&A

Q&A: Unlocking Precision - The Art of Micro servo Driver control

Q1: What is a micro servo, and how does it differ from standard servos?

A1: A micro servo is a smaller version of standard servos, typically offering a limited range of motion, usually around 180 degrees or less. They are lightweight,making them ideal for compact applications like robotics and model making. Their size allows for more intricate designs and placements where space is at a premium, distinguishing them from their larger counterparts, which frequently enough have greater torque and range.

Q2: Why is precise control important in micro servo applications?

A2: Precision control is crucial in applications where exact movement and positioning are required,such as in robotics,drones,and automation. Misalignment or imprecision can lead to malfunctions, reduced performance, or even failure of the complete system. Therefore, mastering the control of micro servos enables engineers to achieve higher functionality and reliability in their designs.

Q3: What are the basic components involved in controlling a micro servo?

A3: Controlling a micro servo primarily involves a microcontroller, a power source, and the servo itself. The microcontroller sends pulse-width modulation (PWM) signals to the servo, determining its position based on the length of the pulse. Additionally, sensors may be integrated to provide feedback and further refine control.Q4: Can you explain the pulse-width modulation (PWM) and its significance in servo control?

A4: PWM is a technique used to control the amount of power delivered to electrical devices, in this case, the micro servo. By varying the length of the voltage pulses sent from the microcontroller, we can dictate the position of the servo motor. Shorter pulses move the servo to one end of its range, while longer pulses direct it to the opposite end. This technique is notable because it allows for precise adjustments to the servo’s rotation and positioning.

Q5: What are some common challenges faced in micro servo driver control?

A5: Some common challenges include signal noise, which can lead to inaccurate positioning, and power limitations, as micro servos may struggle if not supplied with a consistent voltage.Additionally, synchronization among multiple servos can be tricky, especially in complex systems where timing is essential. Overcoming these challenges frequently enough requires careful circuit design and robust coding strategies.

Q6: How can one improve the precision of micro servo control?

A6: To enhance precision, users can implement feedback mechanisms like encoders or potentiometers to monitor the actual position and adjust accordingly. Filtering techniques can also be employed to smooth out any noise in the signal. Moreover, well-designed algorithms that compensate for mechanical play or lag can greatly improve the accuracy of micro servo operations.

Q7: Are there specific applications where micro servo driver control shines?

A7: Absolutely! Micro servo driver control excels in applications like drone flight stabilization, animatronics for entertainment, camera gimbals for smooth video capture, and robotics for tasks requiring delicate maneuvers. Their ability to be controlled with high precision makes them invaluable in sectors ranging from hobbyist projects to advanced industrial automation.

Q8: What advice would you give to newcomers to micro servo control?

A8: Start with a clear understanding of the basics—how servos work and the significance of PWM signals. Experiment with simple projects to gain hands-on experience before moving to more complex builds. Additionally, utilize libraries and tools available in various programming environments to streamline your coding efforts. don’t hesitate to reach out to communities and forums; sharing knowledge and experiences can foster learning and innovation.

By delving into the nuances of micro servo driver control, enthusiasts can unlock the potential for innovation and creativity in their projects, achieving remarkable results through precision and dedication.

Closing Remarks

As we draw the curtain on our exploration of “Unlocking Precision: The Art of Micro Servo Driver Control,” it becomes evident that the delicate dance between technology and artistry is ever-evolving. Mastering this intricate control opens up a world where minute adjustments translate into significant impacts—be it in robotics, custom electronics, or even everyday applications.By embracing the nuances of micro servo drivers, we not only enhance our technical skills but also ignite our creativity, pushing the boundaries of what is possible. Whether you’re an experienced engineer looking to refine your craft or a curious beginner eager to dip your toes into this fascinating realm, the journey into micro servo control invites continual learning and experimentation.

As you take the knowledge gleaned from this article and apply it to your projects,remember that precision is not merely about accuracy,but about understanding the dance of movement,the flow of energy,and the poetry within technology. Here’s to your future innovations—may they be precise, purposeful, and inspiring.